Wireless charging of industrial robots: case study

The world of industrial automation is growing fast, there is no doubt about it. And wireless charging plays one important role for next-generation technologies. From the daily gadgets we use, autonomous robots to all kinds of industrial machines, wireless charging systems eliminate the constraints of cables. With no cables different processes that are happening around us is becoming more seamless and more efficient.

However, designing such systems is no simple task. Engineers face challenges in efficiency, alignment, and thermal management, all of which demand innovative solutions. Although, we might get an impression that everything is evolving fast and with little effort, in reality these solutions take massive effort and time.

In this particular case study we will look into the complexities of wireless charging for industrial robots, with a special focus on large-scale vacuum cleaners. This particular case study is built around the industrial size vacuum cleaners to demonstrate the benefits of using simulation software.

By using simulation software, engineers and manufacturers can uncover solutions to different challenges, revolutionizing their approach to industrial design. Simulating gives an undeniable opportunity to test and improve the ideas that are still in the design phase, in the drawings, allow engineers to test before building an actual prototype of the product.

In the following case study, we’ll explore the critical challenges in designing wireless charging systems for industrial robots, examine how simulation tools address these obstacles, and showcase the transformative results of this approach.

Whether you’re an engineer seeking ideas into optimizing inductive coil designs or a manufacturer aiming to cut development costs, this case study offers actionable takeaways. By the end, you’ll have a clear understanding of how simulation simplifies the design process and enhances performance and reliability, making it an indispensable tool for the future of wireless charging.

What is the challenge?

In an era of advancing industrial automation, wireless charging for industrial robots, particularly large-scale devices like industrial vacuum cleaners (which this case study is focused), is no longer a futuristic concept but a demand of the today’s consumer.

Of course, innovation always bring different challenges.

And here are the few:

- Power transmission efficiency: Wireless charging systems for industrial robots (including large scale vacuum cleaners) require high efficiency to transfer substantial energy over varying distances. Any drop in efficiency can result in prolonged charging times, reducing operational productivity.

- Magnetic field interference: Due to their size and operation, industrial vacuum cleaners generate electromagnetic interference, making it challenging to establish a consistent and stable wireless energy transfer.

- Design complexity: Engineers must design inductive coils and charging systems capable of maintaining optimal performance despite variations in alignment, temperature, and operating conditions.

- Thermal management: Heat dissipation is critical during wireless power transmission to prevent system failures or degradation of components over time.

What is the solution?

Simulation software provides engineers and manufacturers a tool to overcome these challenges.

Now, let’s look into this specific simulation use case for the industrial vacuum cleaner. For this case study we used CENOS wireless charging simulation software (C : WCH). Let’s analyze the images to understand the role of simulation in designing wireless charging systems for industrial vacuum cleaners.

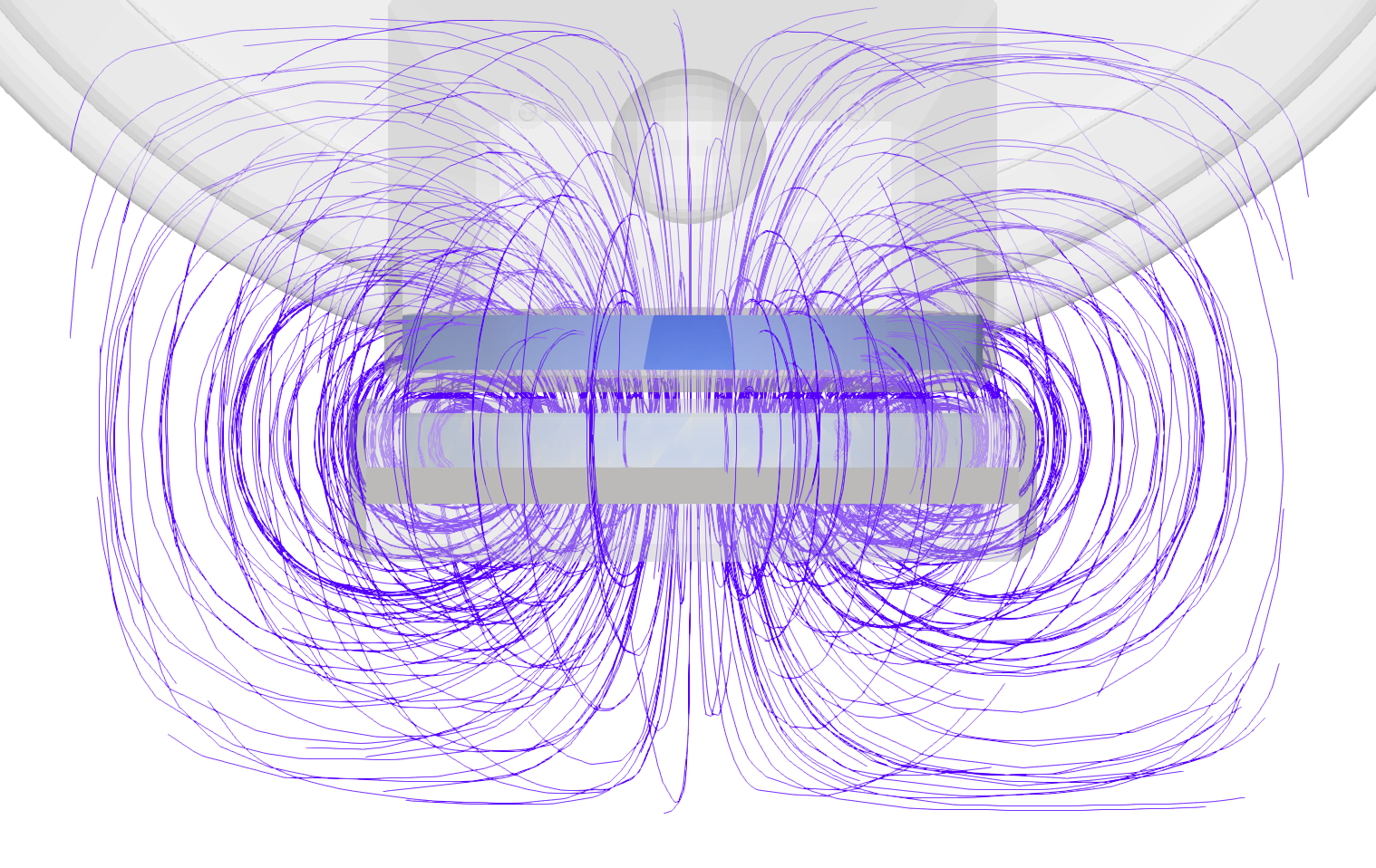

- Image 1

This image shows the magnetic field distribution around the inductive coils during charging. Engineers can observe areas of high and low magnetic flux density, identifying potential inefficiencies in coil alignment. By leveraging simulation, engineers can adjust coil design to optimize power transfer efficiency and reduce electromagnetic interference.

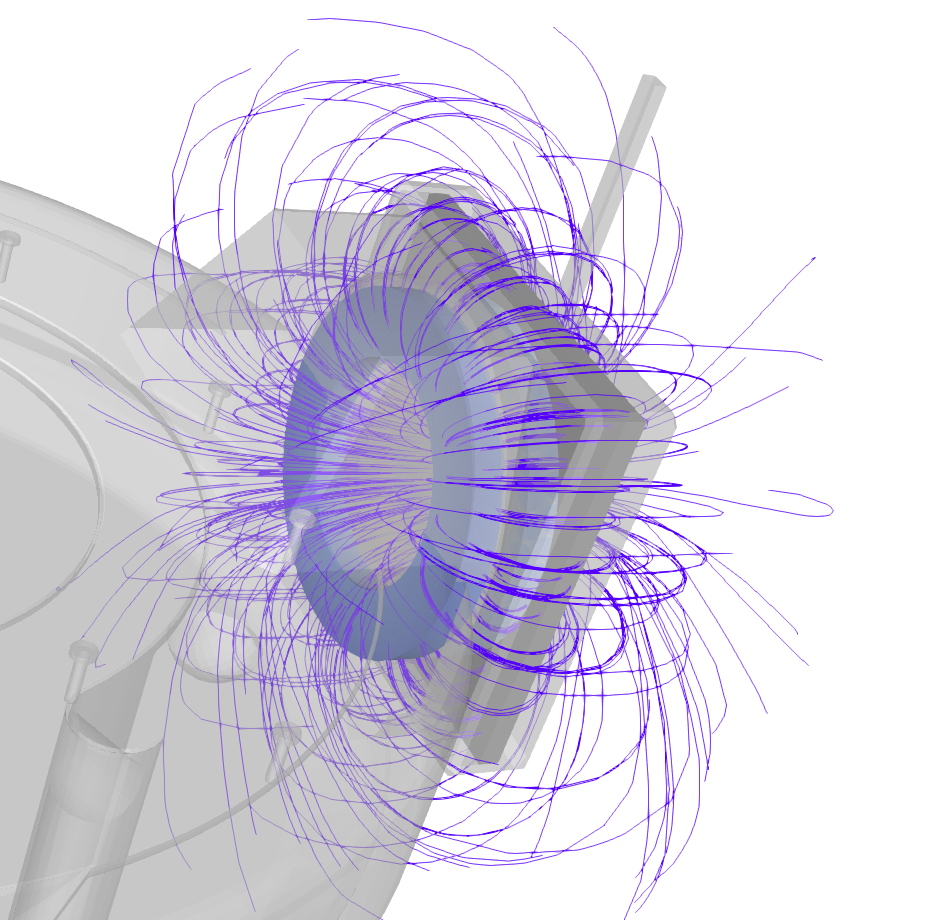

- Image 2

Here, we see a detailed visualization of electromagnetic field lines interacting with the vacuum cleaner’s charging pad. This helps engineers make sure that the system achieves consistent alignment and stability during power transfer. Simulations can highlight misalignment issues, allowing for design corrections before physical prototyping.

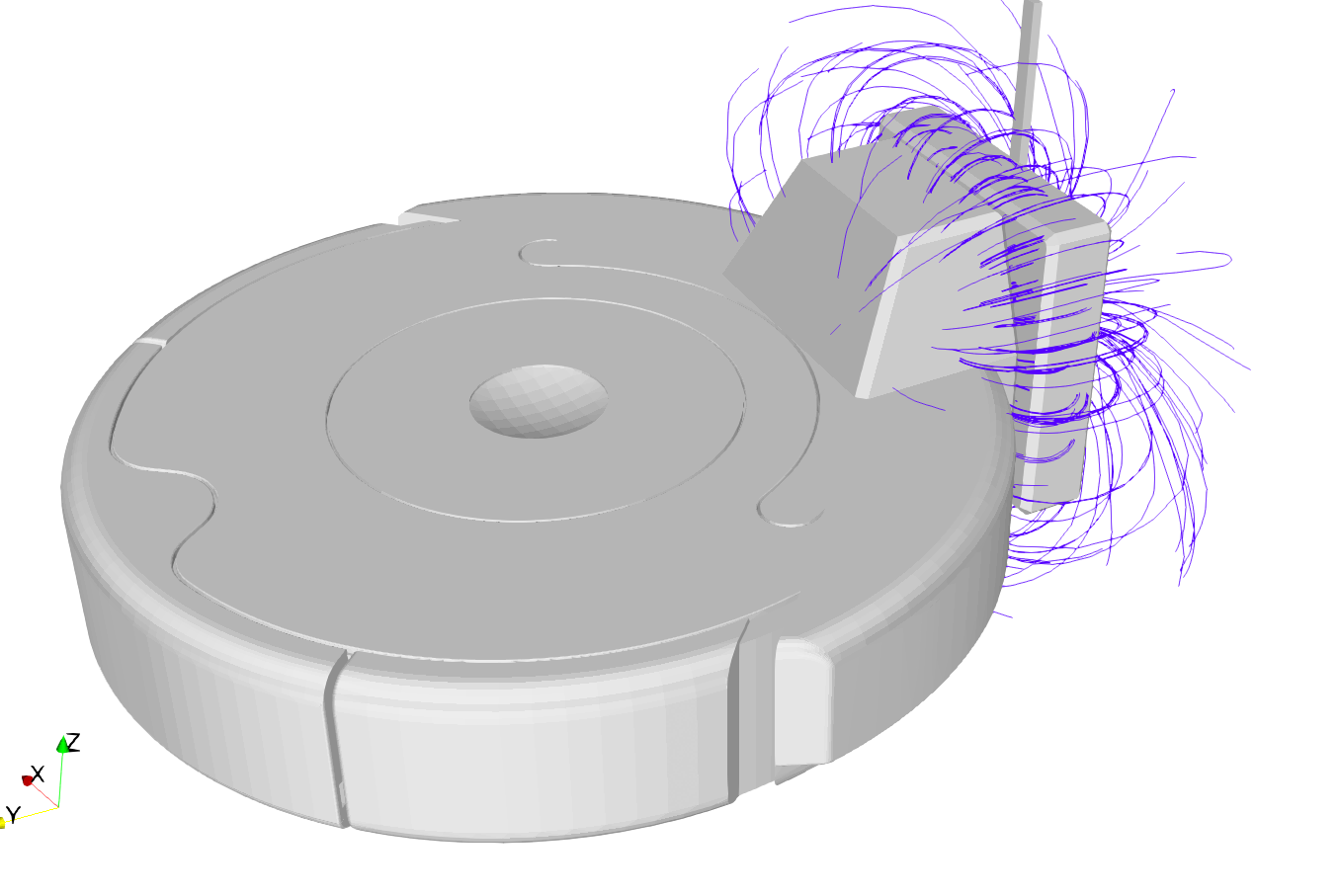

- Image 3

The following simulation image demonstrates the external geometry of the vacuum cleaner along with the charging system’s electromagnetic interactions. By examining these visualizations, engineers can refine the placement and orientation of charging components, ensuring thermal management and maximizing energy efficiency.

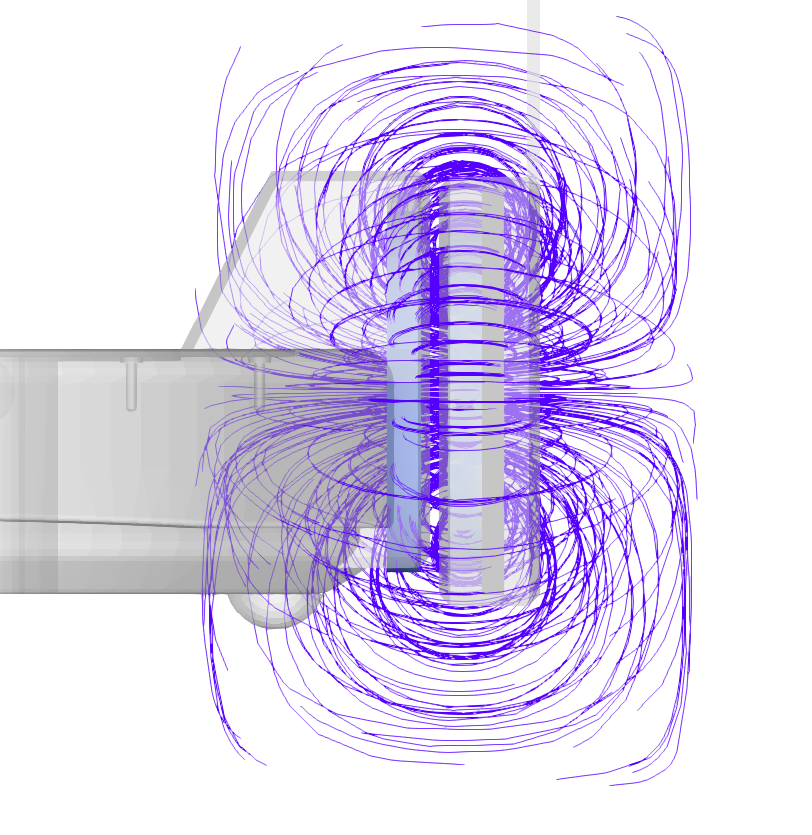

- Image 4

The final image focuses on the charging system’s vertical magnetic flux distribution. Engineers can use this data to balance power delivery across the entire system, avoiding hotspots or uneven energy distribution that could lead to inefficiencies or damage.

Through these simulations, manufacturers can save significant time and resources. Virtual testing allows for the systematic improvement of charging systems without the expense of repeated physical prototypes.

What is the result?

By using simulation software to design wireless charging systems for industrial robots and in this case vacuum cleaners, engineers can see several benefits. And here are the few to point out:

- Enhanced efficiency: Optimal coil design and alignment reduce energy losses, ensuring fast and reliable charging.

- Reduced development costs: Virtual prototyping minimizes the need for physical prototypes, cutting costs and speeding up the development timeline.

- Improved reliability: Simulations identify potential issues, such as electromagnetic interference or thermal overload, enabling engineers to address them early in the design process.

- Scalability: Simulation insights pave the way for the broader adoption of wireless charging in other industrial applications, from forklifts to automated guided vehicles.

In conclusion, the integration of simulation software in the design process for wireless charging systems transforms challenges into opportunities. For engineers and manufacturers tackling the complex demands of industrial-sized devices like in this particular case the vacuum cleaners, these tools are not just advantageous, but they are rather essential.