Validation case by SMS Elotherm: choosing the best workpiece and magnetic concentrator material

Time by time our customers do validation research to match the simulation results with the actual hardening profile. One recent validation project was done by Elotherm – a German induction heating, hardening, and welding company which is part of the SMS group.

With approximately 480 employees, Elotherm, IAS and Tech Induction serves customers internationally at its locations in Germany, Remscheid and Iserlohn, as well as France, USA, Mexico, Brazil, China and India.

Elotherm combines all competences when it comes to induction, their technology is based on compatible modular plant components, which can be efficiently combined into individual configurations for specific induction heating needs.

This validation case was carried out by one of the most competent induction heating engineers and our dear customer – Judith Levermann.

Phase 1 – Calculation

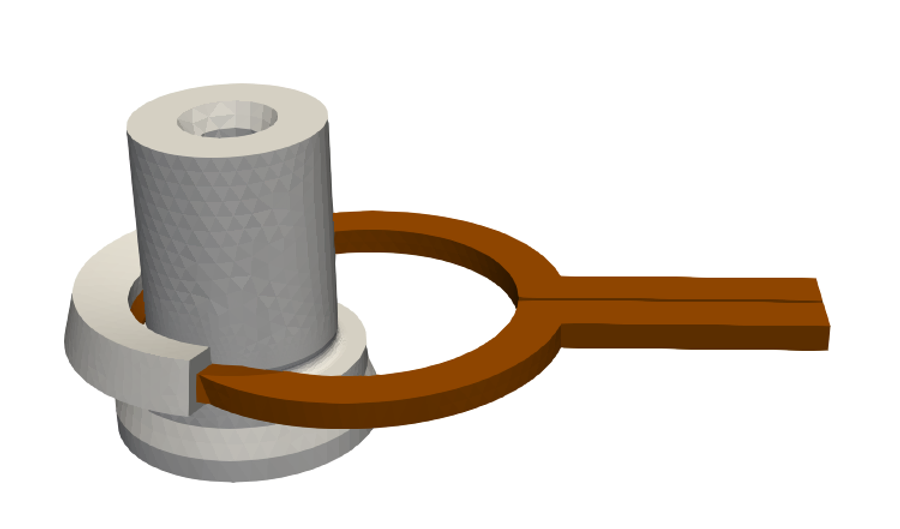

Inductor with magnetic concentrator made from laminated steel sheets

The first task was to determine the best workpiece and magnetic concentrator material. Three different materials were chosen and simulated with CENOS.

Simulation results

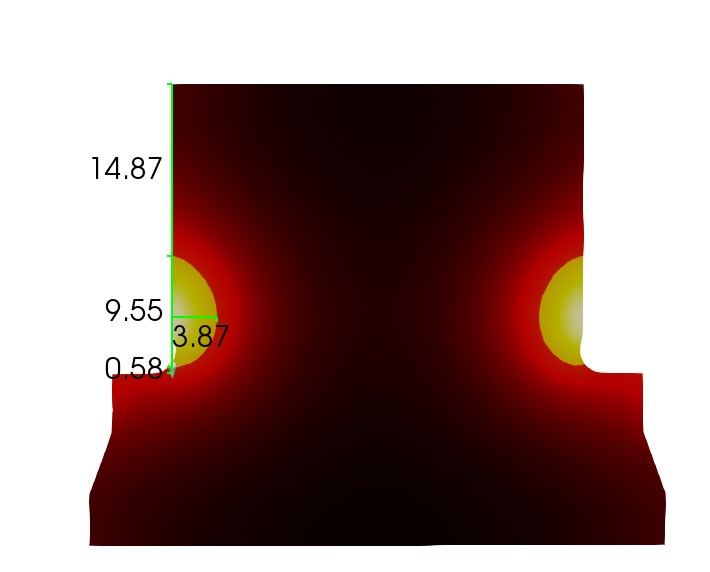

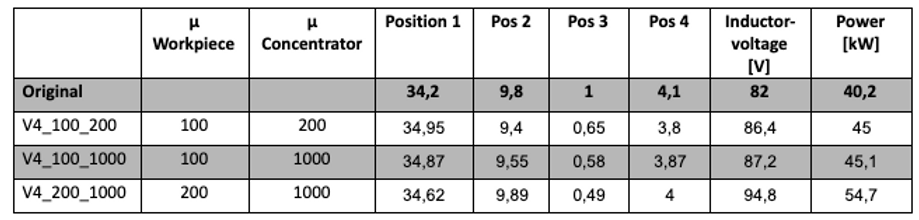

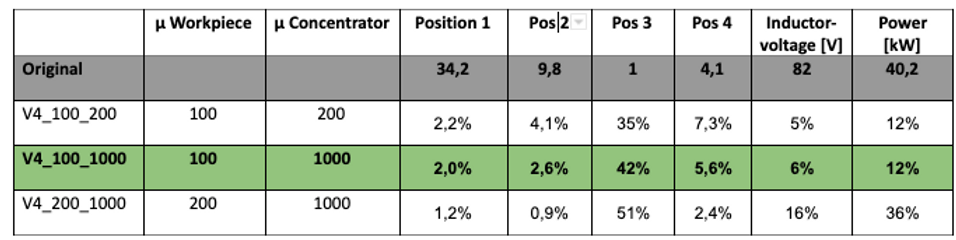

Comparison of different calculations with different permeabilities of the magnetic concentrator and the workpiece

Comparison of different calculations with different permeabilities of the magnetic concentrator and the workpiece

Comparison of different calculations with different permeabilities of the magnetic concentrator and the workpiece

The best result was achieved with the following values:

- µ_workpiece = 100

- µ_concentrator = 1000

Phase 2 – Optical Match

- The isoline of 825 ° C is shown in black and is the transition point for the change in the structure

- The hardness zone of the simulation visually matches the laboratory test

- µ workpiece = 100, µ electrical sheets = 1000

Conclusion

With the help of CENOS engineers can reliably experiment with different parameters and draw conclusions before physical prototyping. Actual results accurately match the 3D simulation when observed visually.