The benefits of modeling: achieving accurate heating parameters for sintering YAG ceramics

Yag ceramics, also known as yttrium aluminum garnet ceramics, are a type of advanced ceramic material that holds immense value in various industries. These ceramics are composed of yttrium, aluminum, and oxygen, and are renowned for their exceptional mechanical, thermal, and optical properties.

Yag ceramics, also known as yttrium aluminum garnet ceramics, are a type of advanced ceramic material that holds immense value in various industries. These ceramics are composed of yttrium, aluminum, and oxygen, and are renowned for their exceptional mechanical, thermal, and optical properties.

Yag ceramics find applications in fields such as laser technology, electronics, aerospace, and medical devices, where their high melting point, excellent thermal conductivity, and optical transparency make them indispensable. With their unique combination of properties, yag ceramics play a crucial role in enabling cutting-edge technologies and advancements in various sectors, making them highly valuable in today’s rapidly evolving world.

Heating simulation is a crucial aspect of many industries, including the production of YAG ceramics. The ability to accurately predict and simulate heating parameters can save time, money, and resources. In the case of an academic user, our CENOS™ Induction Heating simulation software allowed for the testing of different frequencies and susceptor dimensions, ensuring that the heating parameters were accurate and met the requirements set by the user. The benefits of modeling cannot be overstated, and we encourage all industries to consider the advantages of simulation in their processes.

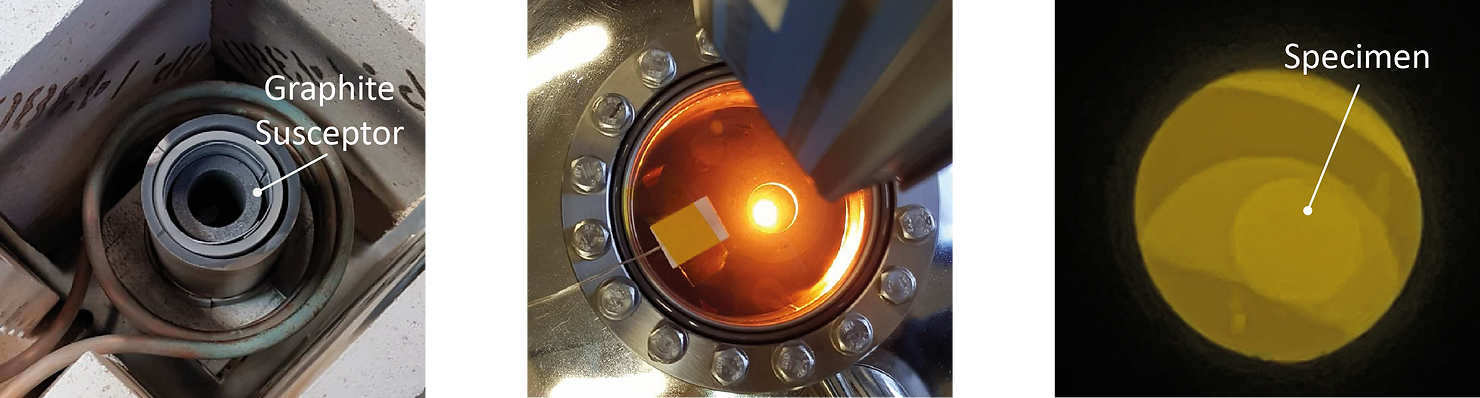

We recently had the pleasure of working with an academic user from the Brazilian Center for Research in Energy and Materials (CNPEM), Vicot Ferrinho Pereira, working on the “Sirius” project (use this link to apply for the free software for non-commercial research and study purposes), who was looking to simulate the heating parameters of a vacuum induction furnace for sintering YAG ceramics. The user had specific requirements for the furnace, including a vacuum atmosphere, a heating rate of 35°C/min, and a minimum temperature of 1700°C.

To achieve these requirements, the induction heating method was used with a graphite susceptor as the heating element for the ceramic specimen. However, the challenge was to find the best fit of frequency and limits of susceptor dimensions to ensure accurate results.

This is where our software, CENOS™ Induction Heating simulation software, came into play. Our simulation software allowed the user to check the best fit of frequency and limits of susceptor dimensions, ensuring that the heating parameters were accurate and met the requirements set by the Vicot Ferrinho Pereira.

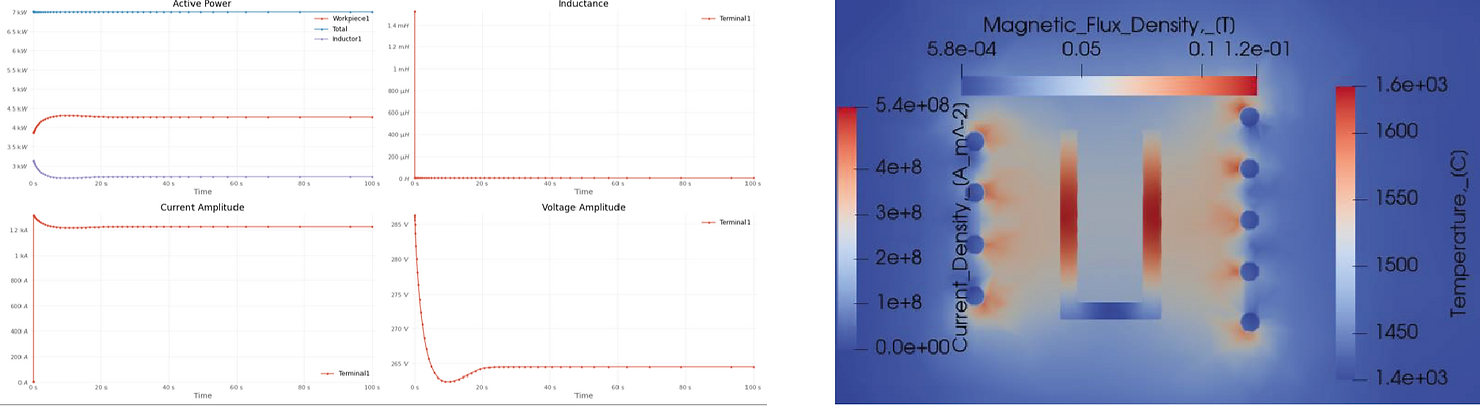

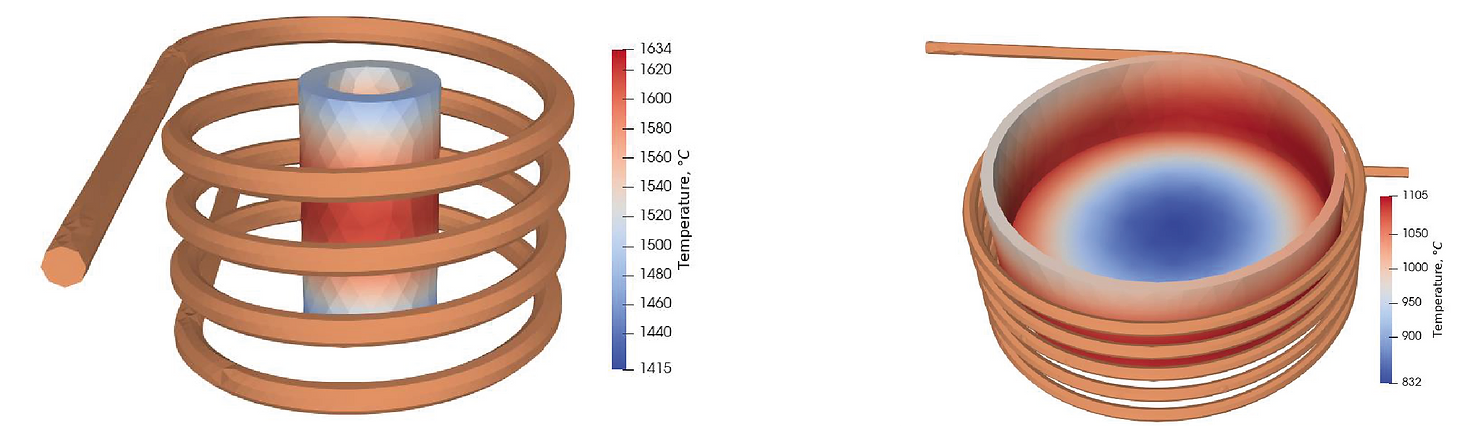

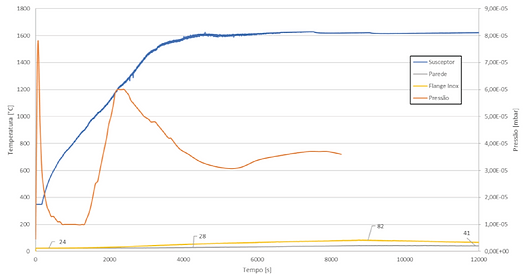

The CENOS™ Induction Heating simulation allowed for the testing of two different systems frequencies, 30 kHz and 250 kHz, and two different susceptor diameters, 30 mm and 100 mm. The simulation allowed the user to check the best fit of frequency and limits of susceptor dimensions, ensuring that the heating parameters were accurate and met the requirements set by the user.

The temperature measured in the simulation reached the original measurement, increasing the power input parameter. The results were very useful for defining the system, but improvements are needed to allow for more accuracy in the test.

The temperature measured in the simulation reached the original measurement, increasing the power input parameter. The results were very useful for defining the system, but improvements are needed to allow for more accuracy in the test.

CENOS™ simulation software results

In summary, our work with the academic user was a success. By using our CENOS™ Induction Heating simulation software, we were able to help the user achieve their desired heating parameters for sintering YAG ceramics. The benefits of modeling cannot be overstated, as it allows for accurate predictions and simulations of complex systems. We are proud to have been a part of this project and look forward to working with Vicot Ferrinho Pereira and other users in the future.