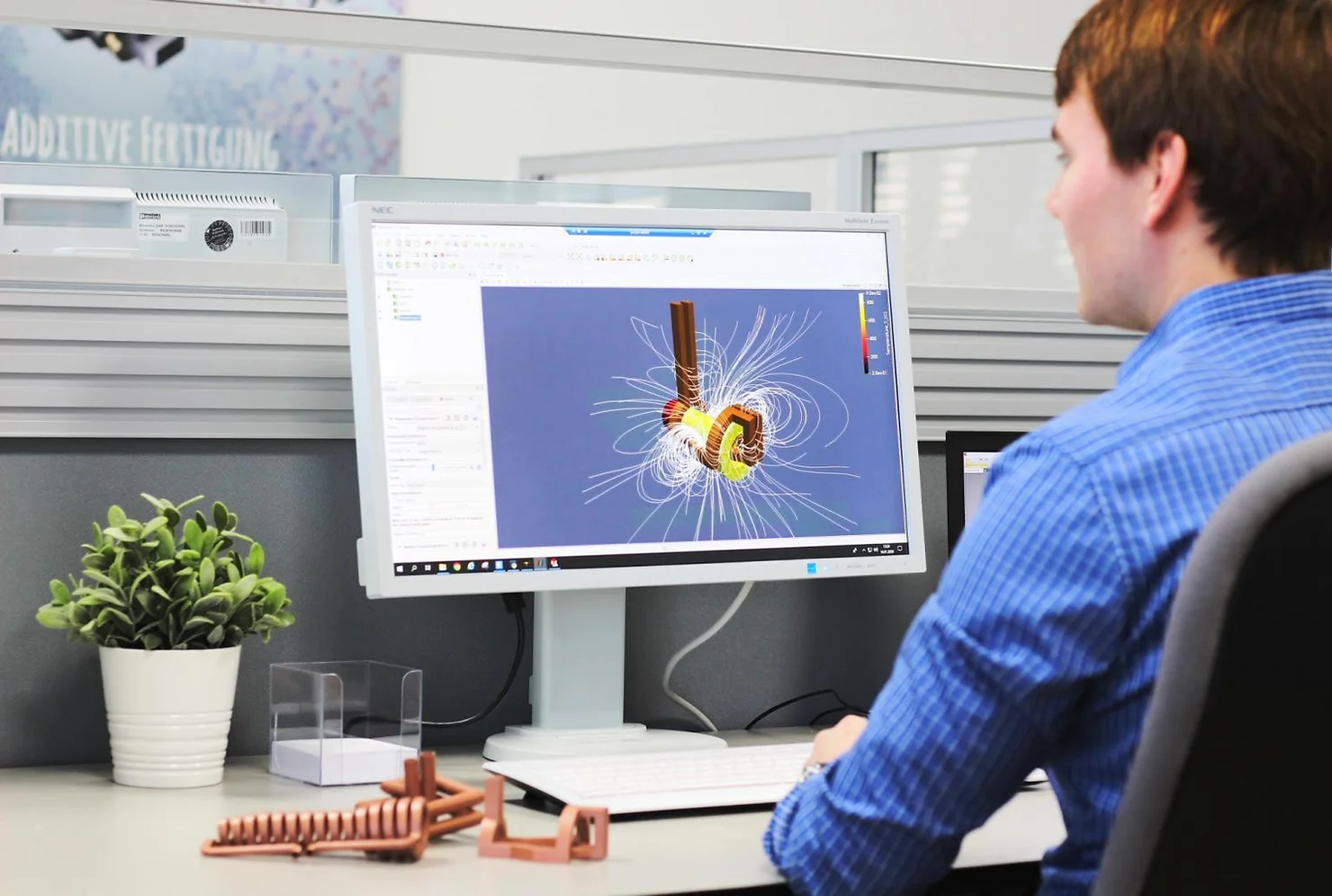

Simulation software and 3D printers make better copper coils

3D printing, also known as “additive manufacturing”, is a hot topic now as it broadens possibilities for on-demand and customized products, even with complex geometries. It eliminates the need for welding, soldering, bending and similar steps in coil design as 3D printers build the object in one piece and in the exact shape as drawn in CAD.

Image courtesy: PROTIQ, software used: CENOS Platform

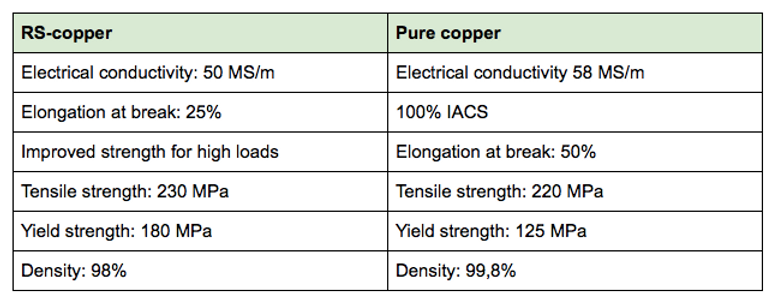

Currently, additive manufacturing is widely used for steel parts and for a long time printing machines were not able to print pure copper items. But now the technology has developed and since the second half of 2019, it’s possible to print-on-demand 100% pure copper coils. Some companies with notable success offering this innovation are PROTIQ and GH Induction.

Main benefits simulations enable together with 3D printing:

- freedom of design,

- optimized geometry,

- more homogeneous heating,

- lower lead time,

- less material wastage,

- cost reduction.

“PROTIQ is processing pure copper by selective laser melting and reaches up to 100% of the international annealed copper standard IACS by achieving an electrical conductivity of 58MS/m. At the same time our parts have a density of more than 99.5% and a thermal conductivity of 400 watts per meter-kelvin.”

Max Wissing, Development Engineer at PROTIQ (Germany)

3D printed copper comparison:

Image courtesy: PROTIQ’s copper element print

Fewer man-hours, faster processes

Coils are a critical part of induction heat treatments as they must be replaced from time to time due to deterioration. This interrupts production and requires several man-hours for recalibration. In comparison to conventional manufacturing, 3D printing induction coils offers great benefits.

First, additive manufacturing provides better reproducibility and higher accuracy compared to the manual bending, which reduces necessary recalibration times. Second, it allows lower cost and faster production of inductors. Finally, using numerical simulation methods, the coils heat pattern is precisely predicted and visualized, helping optimize inductor geometry. This allows making a perfect coil with the first prototype.

Simulation and 3D printing process

Image courtesy: PROTIQ

Simulations as the enabling factor for coil durability

Simulations allow full freedom of design and point out places for improvement in producing a more efficient coil production process. 3D printers build objects layer on layer allowing to make even complex geometries in one piece without soldering. Simulation of the design process allows predicting coil heating, which altogether results in a longer coil lifetime. And because there is no need to bend or join with heat treatment parts together, this also allows eliminating some intermediate steps of the supply chain. Another notable benefit is that the lifetime of 3D printed coils can exceed conventionally manufactured copper coils up to two times, as reported by PROTIQ’s automotive industry clients.

“3D printing unleashes design opportunities for induction coils, while 3D simulation software allows validating design performance. To support our customers with improved coil design, we use CENOS simulation software, since we can rely on the simulation results. We believe that 3D printing of copper will grow even more in significance for coil production, and possibly even become a part of the conventional manufacturing process. We generate new possibilities and advantages for our customers by not only printing the coils for our customers but supporting them with engineering services using powerful simulation software.”

Max Wissing, Development Engineer at PROTIQ (Germany)

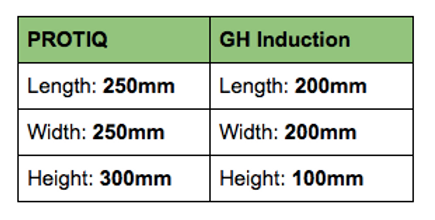

Coil production size and time

Currently, there are only a few copper coil printing companies, because the material is not easily processed in additive manufacturing.

Comparison of maximum copper coil dimension as a 3D print in a single piece:

The possible size of the printed coils varies between really small ones, measuring only a few millimeters, and bigger shapes that are used for example in the automobile industry. Coils that exceed the maximum printable dimensions can be joined together afterward via welding or brazing without problems.

Regards the time, copper coils can be printed within a few days. Compared to the conventional way, which takes up to several weeks, this enables fast-paced product tests and generates flexibility for the customer due to shorter delivery times.

3D printing future forecast

GlobeNewswire market research shows that the global 3D printing metals market is estimated at USD 774 million in 2019 and is projected to reach USD 3,159 million in revenue by 2024. This suggests we will see even more and bigger 3D printed metal parts.

In a larger perspective, Boeing is showing an impressive point that additive manufacturing currently has no limits. Boeing’s GE9X engines are now fully 3D printed, combining more than 300 engine parts into just seven 3D printed components.

Taking into consideration all of the benefits listed above, it really makes one think, won’t additive manufacturing become a norm in the coming decades in many of the traditional manufacturing processes?

Ask our support engineers (info@cenos-platform.com) more about the induction heating simulation capabilities with CENOS Platform and get your first simulation test project done in a few days!