Shorter aerospace composite parts production cycle using induction heating and computer simulation

This article initially was published in Industrial Heating

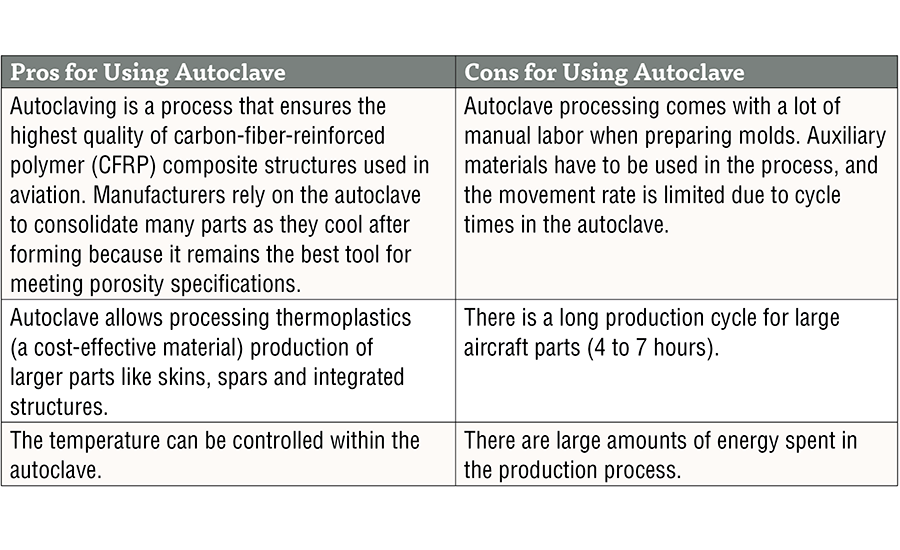

Aerospace manufacturers rely heavily on the autoclave to ensure that their products meet porosity goals. For large parts of thermoplastics (like skins, spars, and integrated structures), this has always been the best way to achieve the compaction and consolidation pressure required, to drive out any volatiles. However, recently aerospace manufacturers are researching the options of producing thermoplastic composites in an Out-of-autoclave press consolidation technique as it reduces the production cycle from 4-7 hours to 10-30 minutes for small and mid-size parts.

For the last three decades, the manufacturing of aerospace structural composites has been using autoclaves to achieve high-quality reproducible parts, including high fiber volume fractions and low porosity. While autoclaves have worked well, manufacturing composites within an autoclave is accompanied by high acquisition and operation costs due to the necessity of a specialized heated pressure vessel to suppress the formation of voids. Furthermore, the capacity of autoclaves limits the size and design of parts, and the production rate is primarily affected by autoclave availability. As a result, there has been an increasing interest in the development of alternative techniques. Out-of-autoclave (OoA) technology is solving these problems for some applications.

What is Out-of-autoclave?

In the broadest sense, the OoA method includes any composite production technology that doesn’t use an autoclave such as microwave heating, induction heating, laser heating, hydroelastic hydroforming, and resistive heating of carbon fibers or carbon nanotube fillers in composites. OoA consolidation provides many advantages over traditional manufacturing methods – relatively short cycle times, efficient heating and cooling, and low initial capital expenditure. Other advantages of OoA technologies are the potential for a higher degree of part integration: for example, the co-molding of skin, stiffeners, and spars in the same operation, which leads to an overall reduction in the total process cycle, with increased production rates.

Additionally, specially-formulated and designed prepregs that can be cured in an oven (out-of-autoclave, or OoA prepregs) have been recently developed to remove the need for an autoclave. The OoA curing can achieve the equivalent thermal and mechanical properties of OoA composites, as the conventional curing method. Moreover, the OoA composite curing process provides a significant reduction in electrical energy consumption by two orders of magnitude.

“We will pursue OoA manufacturing for as many parts as is feasible in the future,” comments GKN Aerospace (Redditch, Worcestershire, U.K.) director of technology, Rich Oldfield. “We see it as a way to bring efficiency to the factory, including an entirely different workflow due to cellular manufacturing vs. large parts queued up for an autoclave.” GKN also sees this flexible manufacturing, which is less reliant on traditional manufacturing monuments, as critical to the task of achieving the forecast 60 to 70 percent composites content on the next generation 737 and A320 single-aisle jetliner programs. (source: https://www.compositesworld.com/articles/out-of-autoclave-prepregs-hype-or-revolution)

Induction heating method

Induction heating can replace the traditional autoclave method for heating and curing large prepreg parts or heating molds for thermoplastics or resin injection. It is used to achieve the necessary temperature of the mold, but it also can guarantee better control over the curing processes, including local heating to accommodate parts with different thicknesses, eliminating hot and cold spots providing fast and homogeneous heating. Even though an integrally heated tool costs slightly more than a standard tool, the benefits of greatly reduced cycle time and freedom from monument constraints deliver an overall economic gain. This technology also is much more conducive to higher-rate manufacturing.

The general benefits of induction heating:

- Heat generation occurs inside the part (mold)

- Heating is contactless—as a result, mold warpage and distortion are minimized

- This method can provide very high power densities

- Heating may be highly selective in the depth and along the surface

- Very high temperatures can be reached

- Short heating times—production rates can be maximized

- Optimized consistency—induction heating eliminates the inconsistencies and quality issues associated with other methods

- Extended fixture life—induction heating delivers heat to very small areas of your part without heating any surrounding parts. This extends the life of the fixturing and mechanical setupEnvironmentally sound without burning fossil fuels—induction is a clean, non-polluting process. Improves working

- conditions for employees by eliminating smoke, waste heat, noxious emissions, and loud noise

- Effective energy consumption—this uniquely energy-efficient process converts up to 90% of the energy expended energy into useful heat. Requires no warm-up or cool-down cycle.

- Closed-loop computerized process control and compatibility with overall process automation

Induction heated mold with cooling channels heats and cools only the mold surface for much faster cycles than are possible with conventionally heated molds. Turning on electric power to the inductors for only a few minutes heats just a 0.2-mm-deep section of the tool surface while 99.9% of the mold stays cold.

However, there are trade-offs when using OoA instead of an autoclave. OoA requires more process study, more parts fabrication work, more investigation to ensure that the resins work properly and often more non-destructive inspection on critical parts.

Steps in designing induction heating system setup

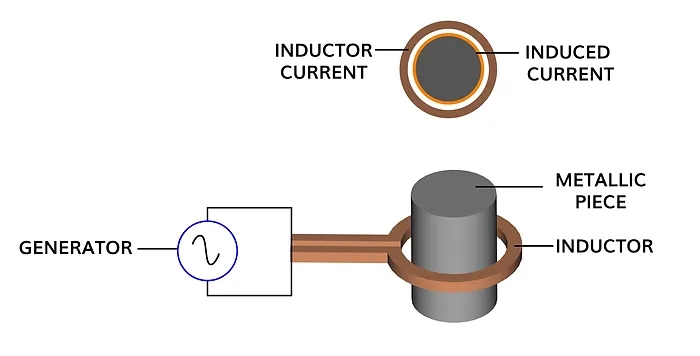

Induction heating is a method where a workpiece is heated up inducing the current in the material itself which results in joule and eddy current heating. This is unlike many other heating mechanisms where heat is transferred through convection or conduction from a separate heat source instead. A typical induction heating setup is displayed in figure 1.

Figure 1

Induction heating is based on a multi-physics process with non-linear material properties varying as a function of temperature this makes it a difficult or even near to impossible process to optimize via trial and error.

Computer simulation is a powerful tool that enables engineers to investigate or design a physical system and/or process using a virtual mathematical model, thus saving time and money on numerous physical design iterations.

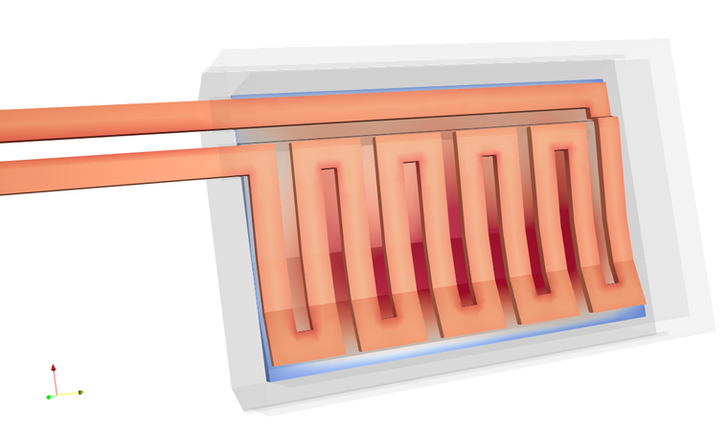

To design the induction heating process a simulation software like CENOS Platform is a must-have. It simulates the electromagnetic field, displaying mold temperature, heating time, cooling time, where to place inductors and cooling channels, and what tool alloy is best suited to the part design and molding material. Usually, mold shells are made from nickel, steel or invar. Inductors are fabricated from copper. Inductor design is one of the most important aspects of the overall induction heating system. A well-designed inductor provides the proper heating pattern for your mold and maximizes the efficiency of the power supply. The performance of an induction heating system is a combination of the specifications of the conductor, inductor, and generator. It is necessary to achieve the correct impedance matching between the coil and the power source in order to use the latter’s full power. The coil designer must also consider that coils need five to ten times as much reactive as active power.

Figure 2 – A 3D simulation by CENOS software – copper inductor and heat distribution on a mold plate

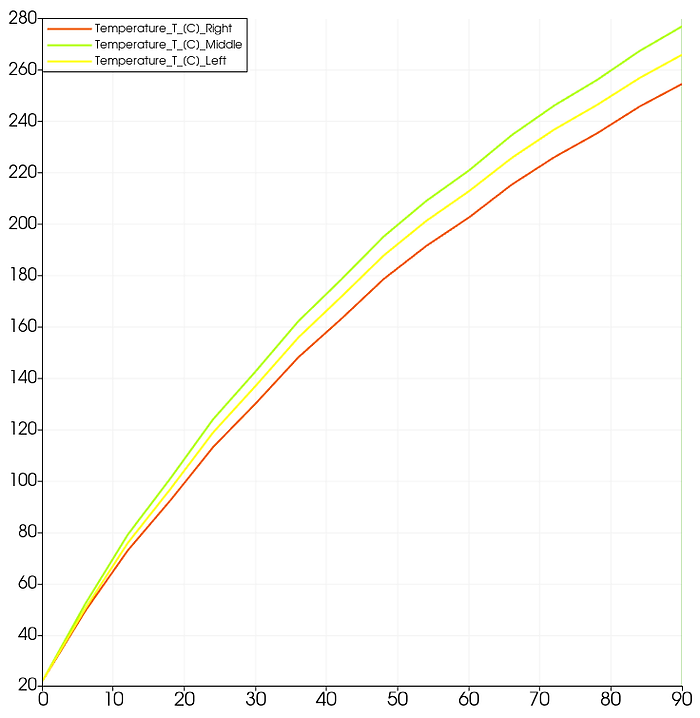

Figure 3 – Simulation software created plot demonstrates how the temperature of 280 °C is reached in 90 seconds in 3 different spots on the mold plate.

Steps in designing

- Define the type of thermoplastic material that defines the maximum heating rate of the material.

- Define mold material and rough volume needed to withstand clamping force and accommodate eventual cooling channels. The chosen cooling method will also influence the critical volume of the mold.

- Estimate the maximum power required for the generator and pick a generator based on this estimation.

- Measure, retrieve material data as a function of the temperature of mold material. Material properties at room temperature for the coil.

- Simulate and optimize heating patterns to thermoplastics composite requirements based on the variables.

- Decide on mold cooling – a) via cooling channels or b) use the cooling capacity of the coils to cool down the mold.Manufacture mold and coil, optimize

- generator to coil, and mold to a specific frequency.

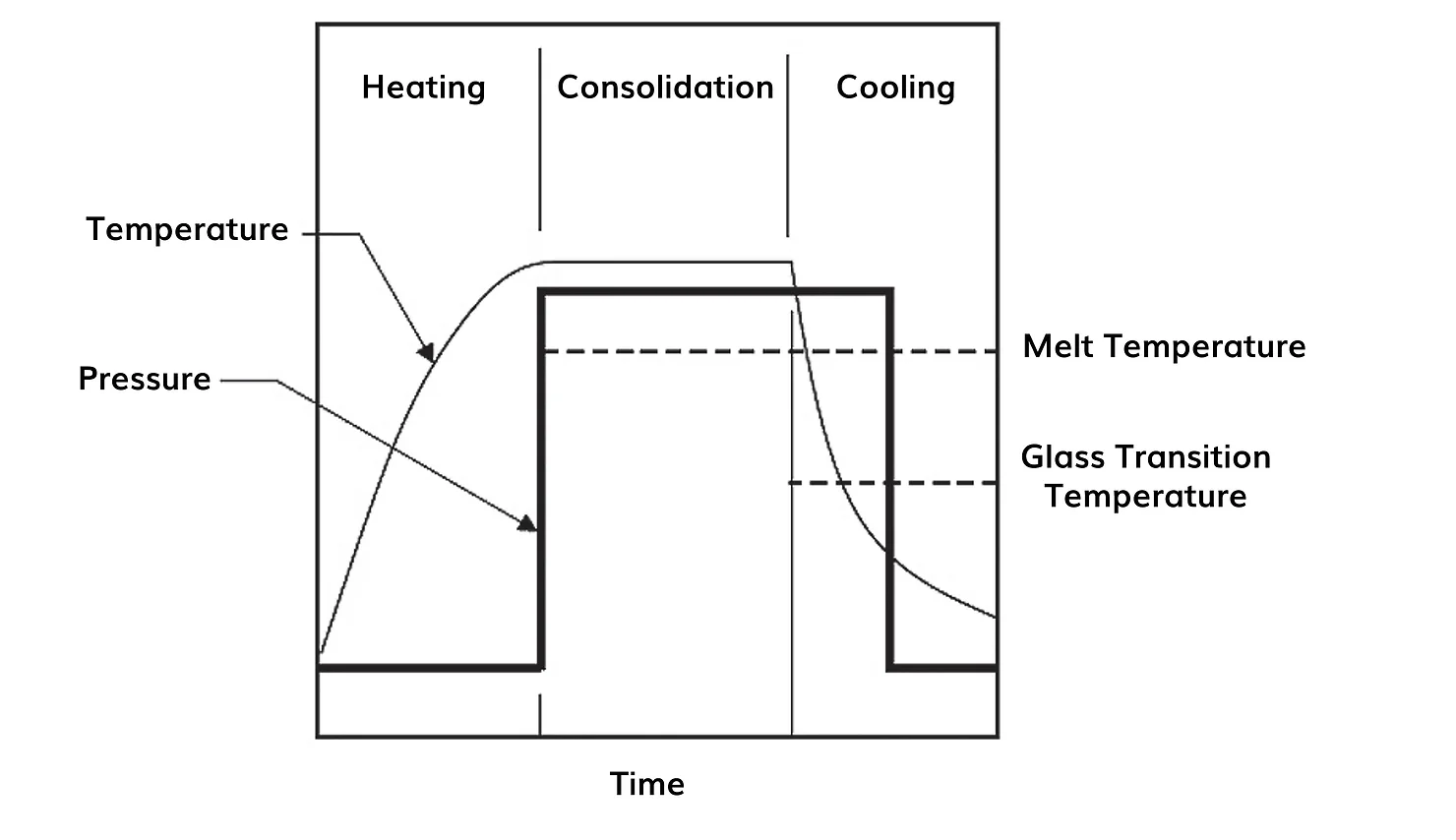

Figure 4

Thermoplastic composites have the typical consolidation cycle, shown in figure 4. The plastic has to be molten in the heating phase, then kept under a certain temperature under pressure for a given time specific for a type of plastic required to retrieve the mechanical properties of the composites. After the consolidation phase, the plastic has to be cooled down to a certain temperature before it can be released from the mold. The rate of the heating and cooling steps are specified and required to get the desired quality of the composite.

The induction heating generators are limited in their maximum power, maximum effective current at the coil, and maximum frequency which are important parameters for the induction heating, simulation software can help engineers to determine the right parameter values.

Autoclaves and large presses (over 2 meters in length capacity) require large capital expenditure. Alternatives with lower initial costs and faster cycle times are being increasingly sought. OoA consolidation provides many advantages over traditional manufacturing methods; relatively short cycle times, efficient heating and cooling, and low initial capital expenditure.