Preheating of substrate for DED and laser cladding processes

CEIT is a research center located in San Sebastian, Spain, affiliated with the University of Navarra, with 230 employees working on multi-disciplinary applications in the fields of materials, manufacturing, transportation, energy, water, health, and ICT.

The Advanced Powder Metallurgy and Laser Manufacturing group of CEIT leads the center’s activity in Additive Manufacturing and laser cladding. The CEFAM project, sponsored by the Spanish Government, supports the development of novel processing routes for Ni alloys using the Directed Energy Deposition (DED) laser process to make solid parts.

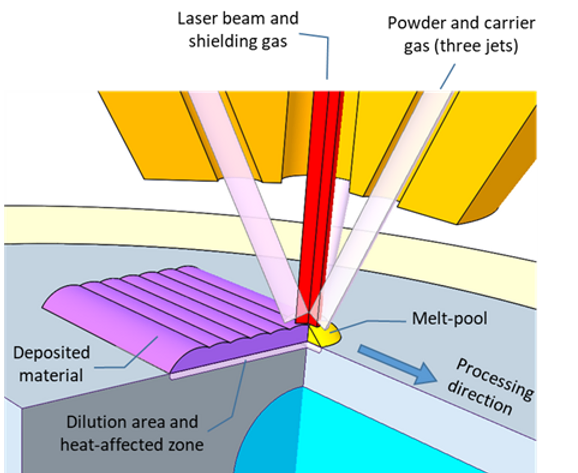

In the DED laser process, a constant flow of powder is directed to a target spot where it is melted by a high-power laser beam, creating a melt pool that solidifies rapidly creating a layer of new material.

DED laser process (Courtesy of CEIT)

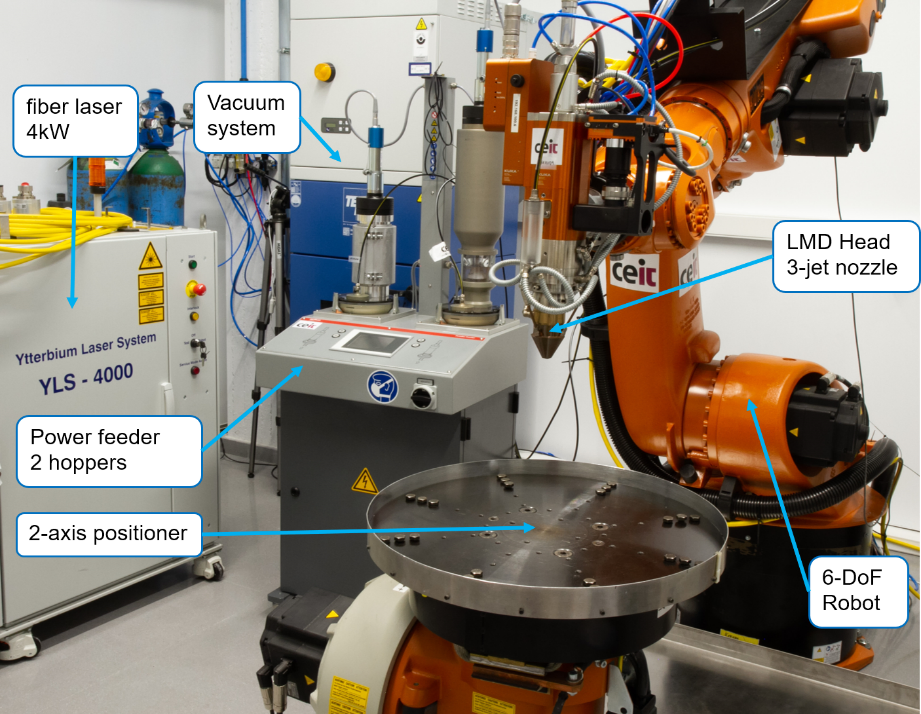

CEIT’s laser cell for Additive Manufacturing

Due to its excellent mechanical strength and resistance to corrosion, wear and oxidation, Ni-based superalloys are commonly used in high-temperature applications in the aerospace and energy sectors.

Among the objectives of the CEFAM project is the optimization of the process parameters of Ni-based alloys and superalloys, including height control of deposited layers, the optimization of the microstructure and the absence of porosity and defects.

Large residual stresses generated in the DED process often lead to cracking. The preheating of the substrate is an effective way of reducing residual stresses and may become key to success in the processability of some Ni-based alloys and superalloys, especially those with low weldability. Induction heating is the preferred option to produce fast and consistent preheating.

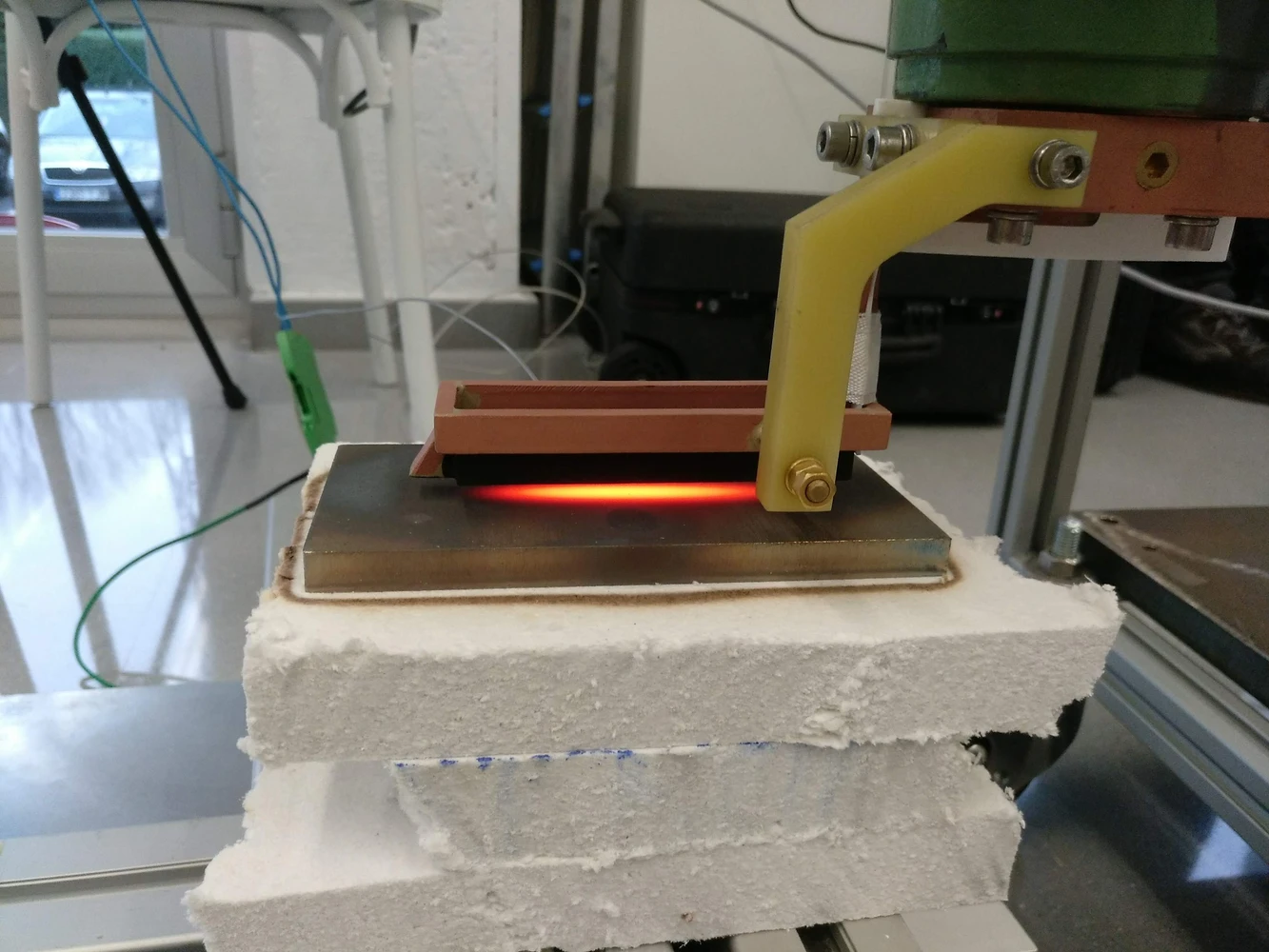

CEIT’s objective is to attain a target preheating temperature at the precise location of the laser spot. In laboratory tests, preheating of the whole base plate is efficient, simple and easy to implement, but this approach cannot be applied to larger parts with more complex shapes.

In such cases, preheating of the whole part is either impractical or undesirable and, therefore, heat must be concentrated around the region to be processed and must travel with the same scanning velocity as the nozzle. The precise determination of the induction power needed to attain the target temperature is a challenging task that needs a powerful simulation tool like CENOS Induction Heating.

Prof. Alejo Avello has carried out detailed simulations of the heating process to determine the temperature history of each point in the substrate, which is an essential information to control the necessary amount of heating. A hairpin inductor with a flux concentrator scans the surface of the substrate and rapidly heats a short strip of material.

As the inductor travels forward, the material left behind radiates and diffuses heat, quickly loosing temperature. Since the DED nozzle trails behind the inductor by a few centimeters, the exact temperature on the surface can be determined in this way.

Temperature field on the surface and inside the material during the scanning process.

Temperature field on the surface and inside the material during the scanning process.

Temperature field on the surface and inside the material during the scanning process.

What can be read from the simulations?

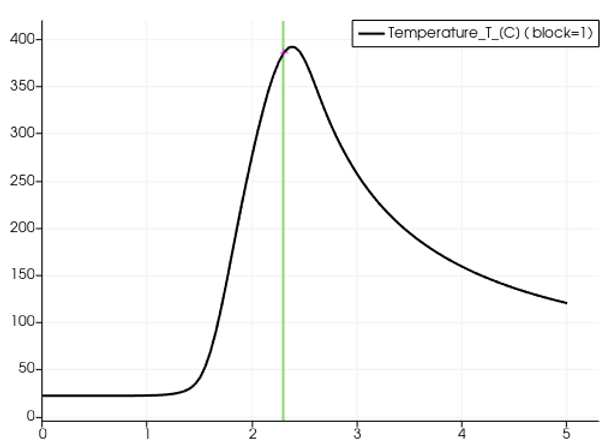

Temperature magnitude and distribution

- Near the inductor, you see intense red-to-orange areas corresponding to temperatures close to 400 °C. This is where the magnetic field is strongest, causing localized induction heating.

- The temperature quickly falls off to cooler blues and greens, dropping below 200 °C only a few millimeters away from the coil. This steep gradient underscores how rapidly the heat diffuses or radiates away once the inductor has passed.

Heat-affected zone (HAZ) shape

- The heated zone is relatively narrow (just a few millimeters wide in each image), indicating that the induction coil and flux concentrator are effectively focusing the magnetic field into a small region.

- This narrow HAZ is crucial in DED processes: you want enough heat to mitigate residual stresses (which often cause cracking in Ni-based superalloys) but not so much that the substrate overheats or distorts.

Relevance to the DED nozzle position

- In practice, the DED nozzle follows the inductor by a few centimeters. These simulations help confirm that by the time the laser beam and powder reach the spot, the substrate is preheated to an optimal temperature (e.g., 200–400 °C).

- If the part cools too quickly (dropping below 100 °C too soon), residual stresses remain high. Conversely, if it stays too hot, you risk other metallurgical issues.

Preheating strategy for complex parts

- The images illustrate a laboratory scenario where the whole base plate might be heated, but in real industrial applications with large, complex shapes, you want this focused heat to “travel” with the nozzle.

- This is exactly the challenge: predicting the power and coil design needed so that only the region under the DED nozzle is at the target temperature. The simulation helps fine-tune the induction power and scanning velocity to achieve that.

Temperature variation over time in a point on the surface.

Conclusions

Perspective vs. orientation

- First image (more of a top or corner view): Shows the elongated “hot trail” on the surface. You can more clearly see how the heat dissipates behind the coil in the direction of travel.

- Second image (slightly angled side view): Emphasizes the depth and lateral extent of the heat in the substrate. You can see how the temperature penetrates into the material below the coil.

Heat gradient emphasis

- In the first image, the focus is on how quickly the substrate cools off behind the coil, highlighting the rapid temperature drop-off (green to blue) just a short distance from the inductor’s path.

- In the second image, the hottest region (red band) appears somewhat broader underneath the coil. This view is useful for engineers wanting to check how deep the heat might be penetrating and whether the target temperature is reached a few millimeters below the surface.

Since this work is still in an early stage, no validation data is yet available, but CEIT scientists believe that CENOS simulation will provide valuable information to develop better processing parameters for the DED laser process of Ni-based alloys.

Prof. Alejo Avello uses CENOS Induction Heating simulation software under Academic License, which is available for free to all non-commercial and academic projects.

The project CEFAM has been funded by the Spanish Ministry of Science and Innovation under the Awarding and funding program for Excellent Technology Centers ‘Cervera’ (Grant CER 20191005).

Why this is interesting for engineers

Thermal management

Managing heat input and distribution is one of the most challenging aspects of metal additive manufacturing—too little preheat leads to cracks, too much can degrade microstructure or cause distortion.

Practical insights

Seeing how quickly the temperature transitions from 400 °C at the inductor to near-ambient just a few millimeters away underscores why real-time monitoring or simulation is vital. It’s a delicate balance to keep only the active region hot.

Scalability

The same principles shown here—localized induction heating, short travel distances, rapid cooling—apply when scaling up to more complex geometries. Engineers can use these results to design custom coils for large parts or for specific Ni-based superalloy compositions.

In summary, these simulation images vividly demonstrate how localized induction preheating can be modeled and controlled, giving engineers the critical temperature data they need to optimize the DED process parameters. The two images differ in perspective and highlight different aspects of the thermal gradient, but both underscore the importance of precise power and positioning to maintain an ideal preheating temperature for Ni-based alloys.