Optimizing an induction cooker coil efficiency with simulation software

The power and precision of the induction cooker technology comes from an electromagnetic field below the glass cooktop surface that transfers current directly to magnetic cookware* causing it to heat up.

Essentially, induction cuts out the intermediate step of heating up a burner and then transferring the heat to the pot.

Home cooks have been warming to induction because it cooks faster and responds much faster when you dial back the temperature.

Induction cooktop advantages:

- Speed – The speed of cooking is the biggest selling point of this cooking appliance. It takes less time to cook food as it heats up faster. Unlike electric and gas cooktops, an induction cooktop doesn’t need another thing to transfer heat, but rather it produces heat straight in the pan. Since the pan heats up faster, cooking will take up to 50% less time.

- Energy efficiency – Induction cookware is more energy efficient as compared to electric and gas in terms of the heating processes, saves energy consumption and reduces power bills. It does not create too much heat in your kitchen; thus, you won’t sweat while cooking.

- Safety – The induction cooktop has no apparent flame on its top and no gas leaks. Likewise, touching the stove top won’t burn your hands because it does not get hot at all. As soon as you turn the dial on, the pan heats up quickly, just as swift as cooling down when the dial is turned off.

So how can we use CENOS Platform induction heating simulation software to optimize induction cooker?

We will demonstrate with this example created by our engineers:

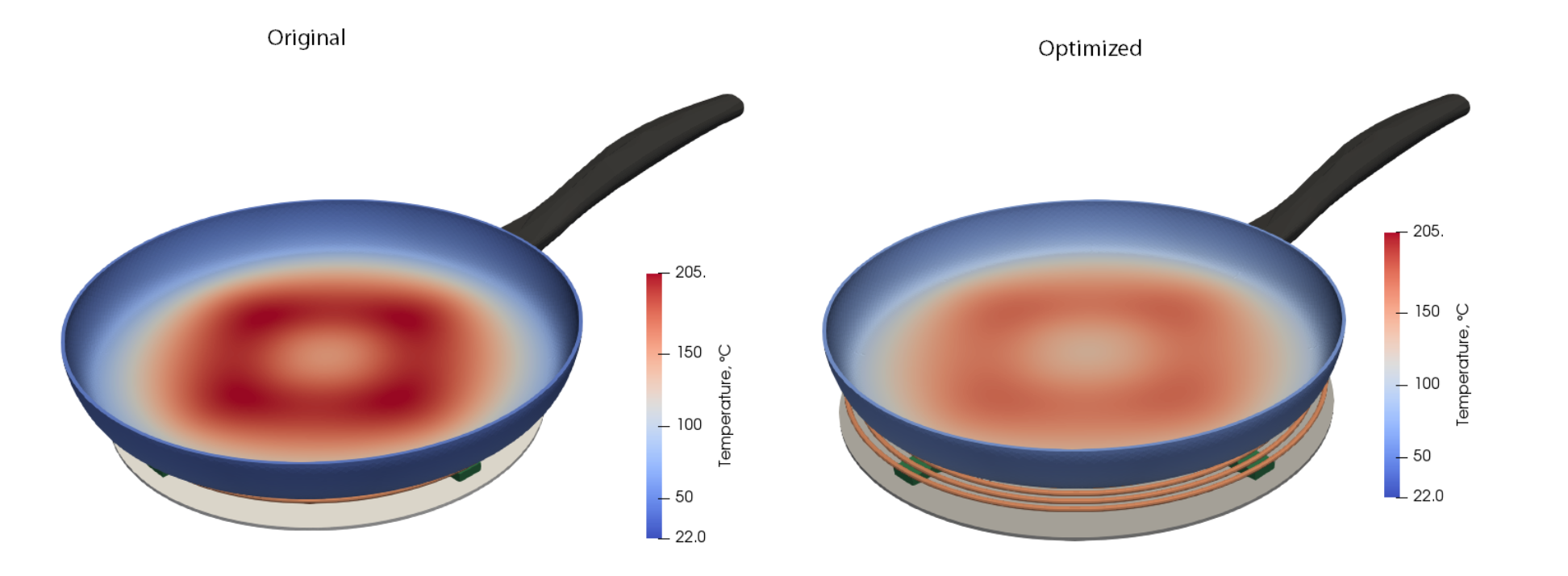

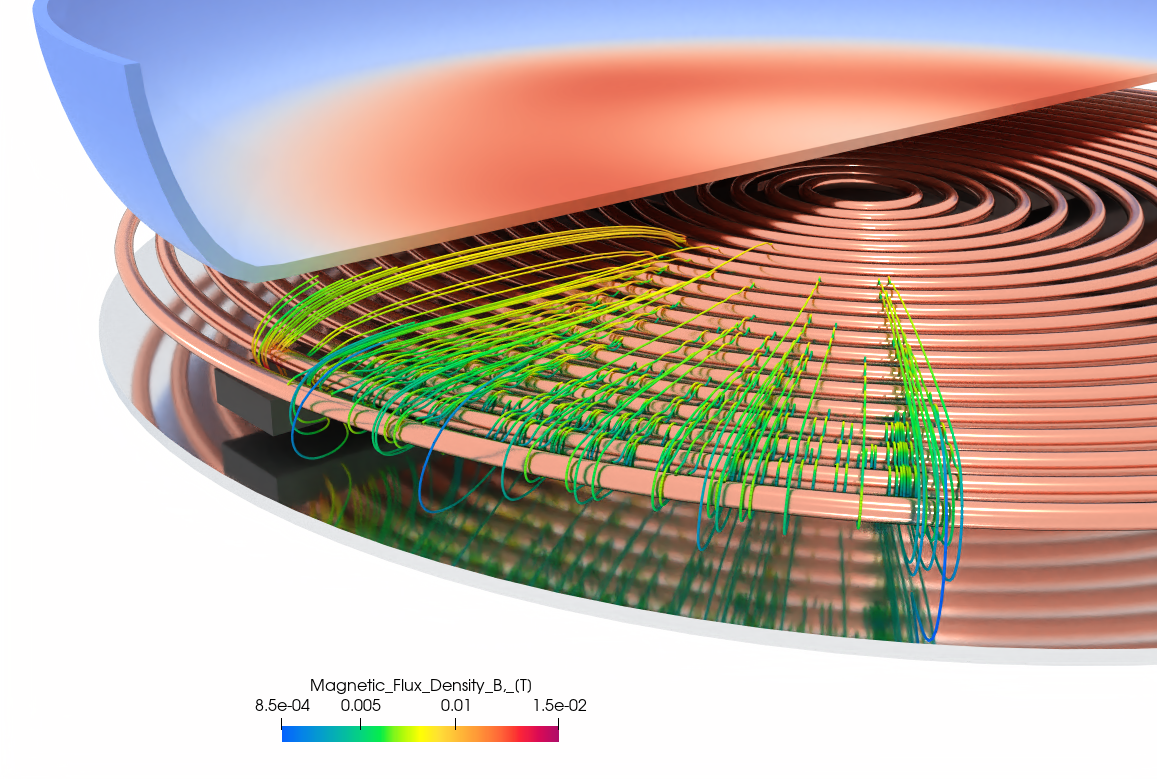

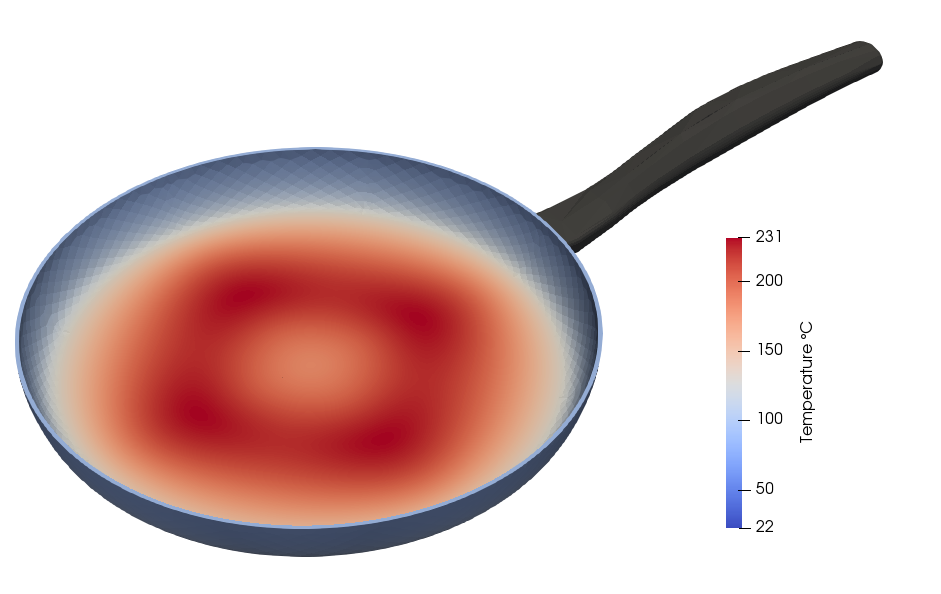

A simulation was created of a 10-inch pan on a 20 winding litz-wire induction coil. The simulation is of a 50s heating period at 40 kHz with an empty pan.

From the first results it was clear that the heat distribution was not optimal, so a fifth ferrite was added in the centre and the coil windings were distributed further inboard.

After these quick changes the difference between the hottest and coldest edge point changed from 158°C (316°F) to 112°C (233°F).

The performance of the cooktop was also analyzed at different frequencies from 32kHz to 50kHz in order to see if and how the heat distribution changes.

The results show that at 50kHz the difference between the hottest and coldest point was 18°C smaller than at 32kHz, however the pan overall was approximately 30°C hotter.

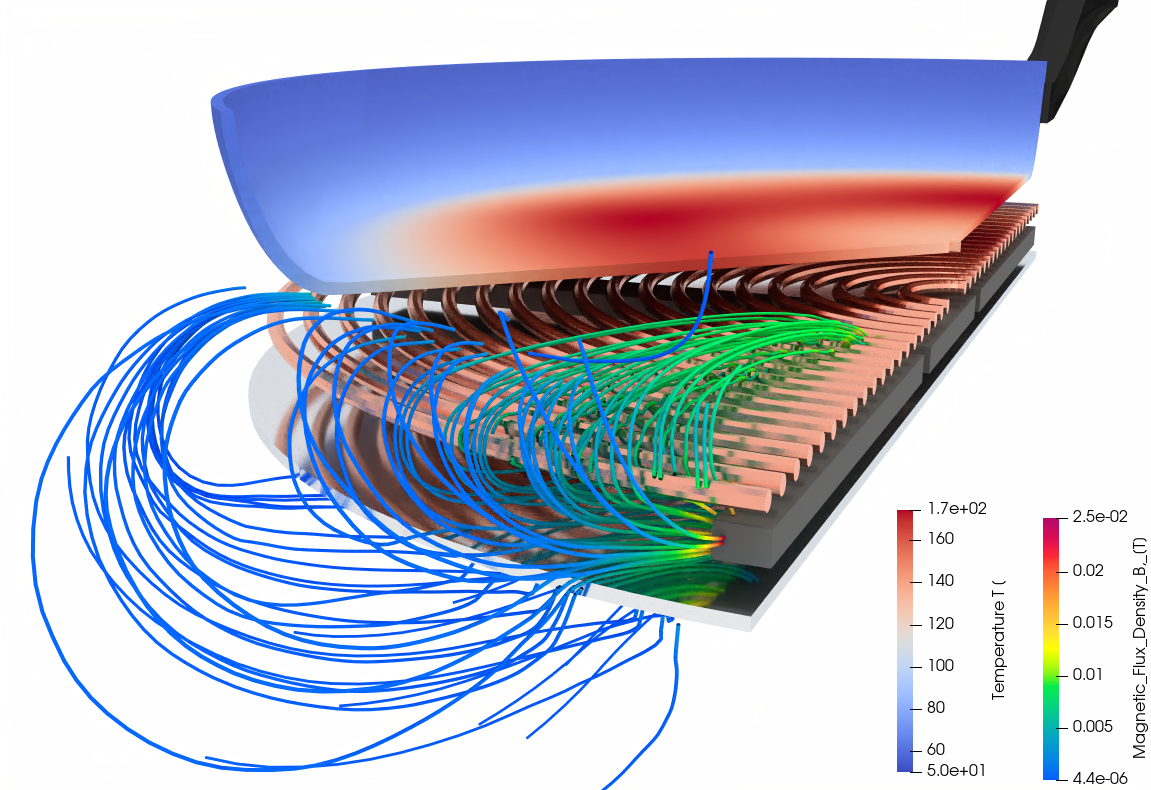

CENOS allows easy visualization of physical effects otherwise invisible in the real world. This allows engineers to make more informed and objectively evaluated design decisions. As there could be tens of even hundreds of different combinations of design parameters, testing these experimentally would be too time consuming and expensive.

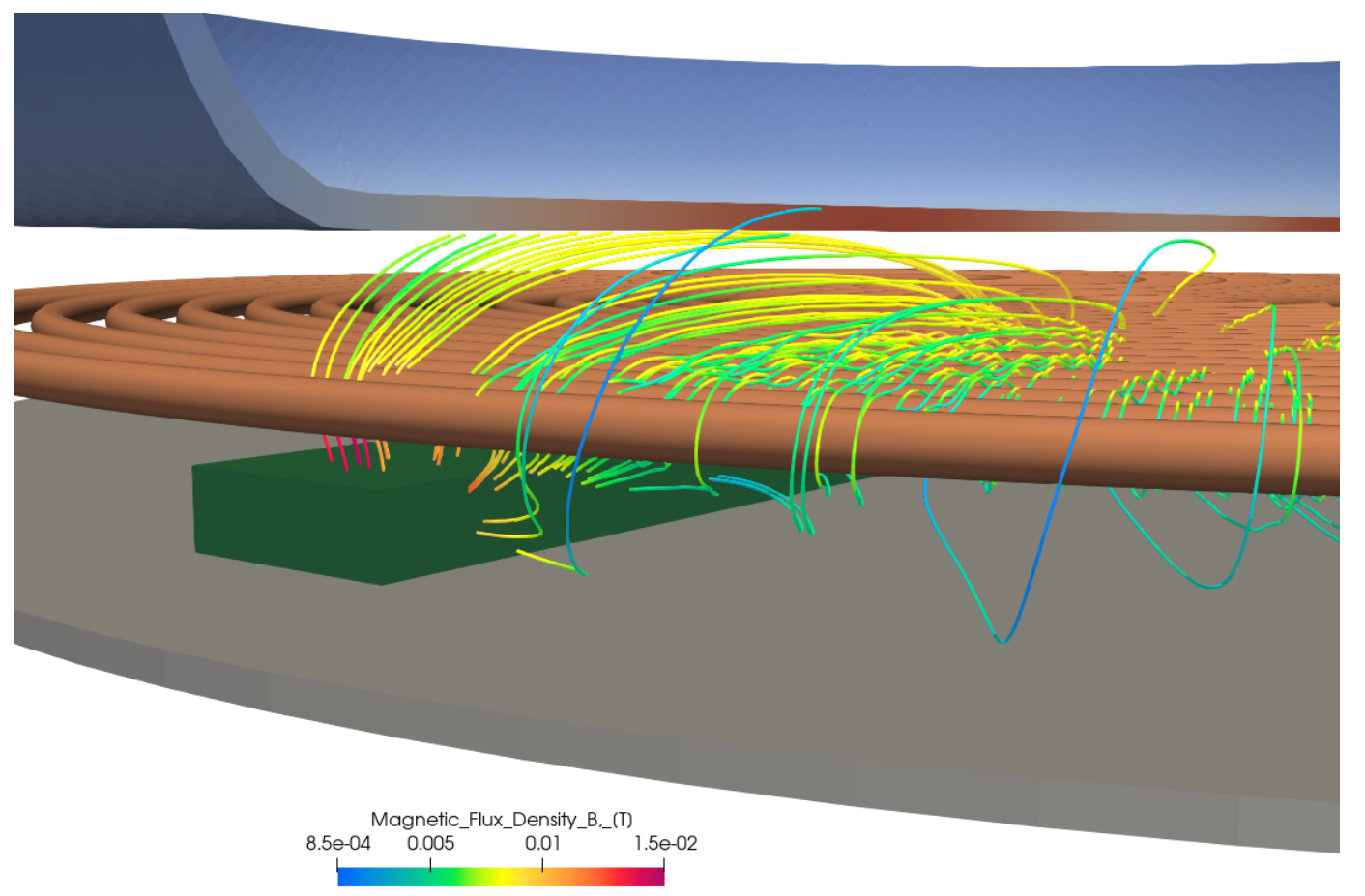

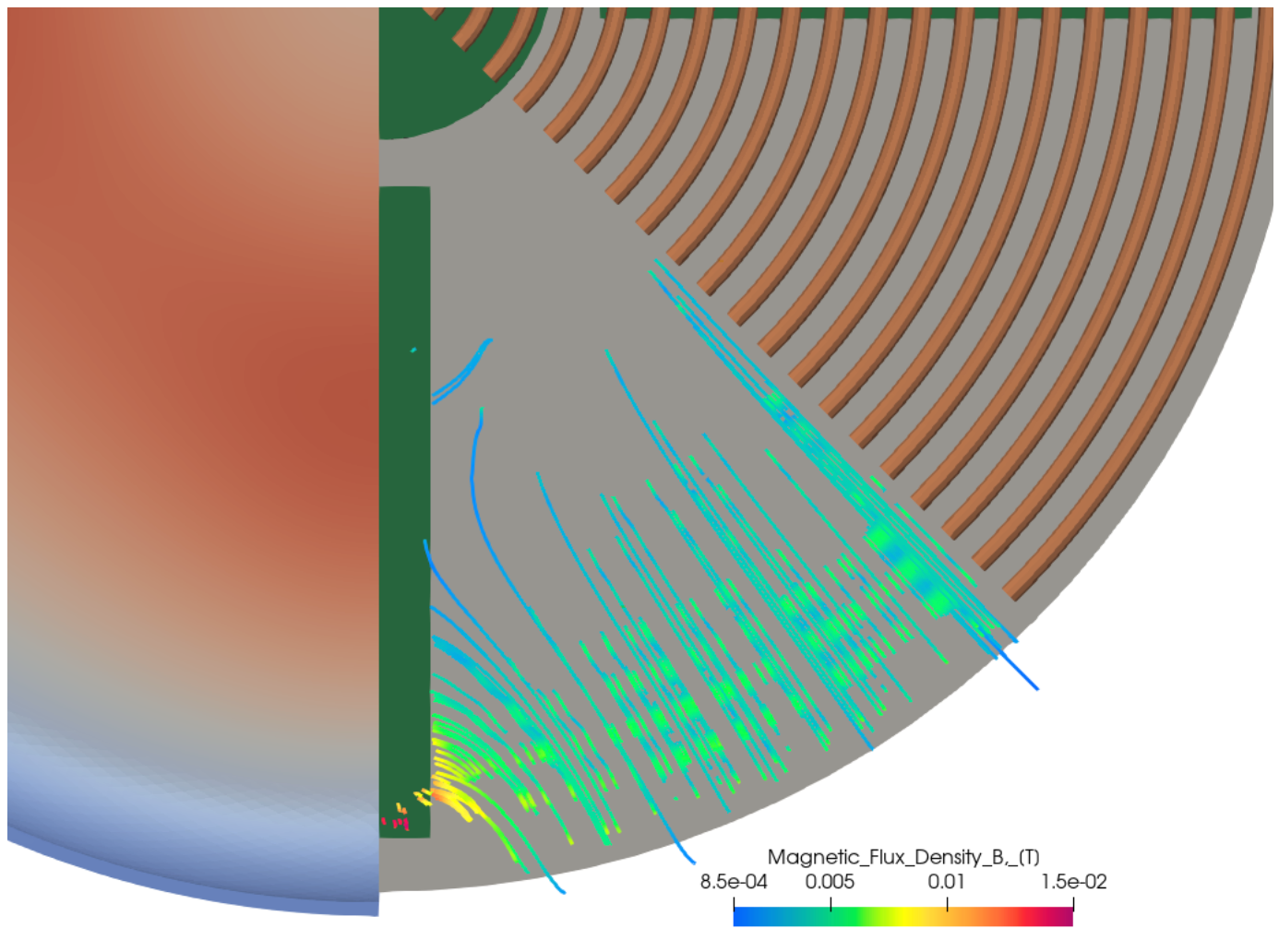

Magnetic streamlines visualized:

Magnetic field lines visualized:

* cookware that is made of a magnetic grade of stainless steel, if a magnet sticks well to the sole of the pan, it will work on an induction cooking surface.