Induction shaft scanning: case study

Precision is important when it comes to hardening steel bars, particularly in industries like automotive and also others. Induction scanning hardening is a process where steel shafts and gear components are progressively heated as they move through an induction coil, followed immediately by rapid cooling using a precisely positioned quenching system.

In this particular case study we analyze how using simulation software can improve the process of induction scanning hardening of a shaft.

Unlike single-shot hardening, where heating and cooling are done in a row, induction scanning requires simultaneous heating and cooling cooing to follow the heating with the spray shower attached next to the inductor, which moves along the shaft. The dynamic nature of this process demands some multi-step control over factors like frequency, speed, and power.

Additionally, the cooling system, including the design of the spray shower, must be precisely engineered to achieve the desired hardness profile.

What is the challenge?

In traditional approaches, these parameters are tested through a make-and-test process. Engineers harden a prototype, then cut it open to study the hardness profile. If the profile doesn’t meet specifications, the material is scrapped. This approach is a costly, time-intensive process that can generate a significant amount of waste. The challenge, therefore, is to optimize each step and minimize scrap material without compromising on quality.

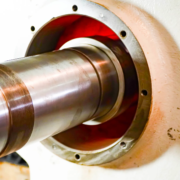

This video shows what the typical shaft hardening process looks like.

(Video credit: YouTube channel of Heat Treating Corp).

What is the solution?

CENOS Induction Heating simulation software eliminates the need for physical prototyping by allowing engineers to simulate the entire induction scanning hardening process. By importing CAD files of complex geometries, such as a splined shaft, engineers can set up and run simulations in less than two hours (depending on size and complexity of the part, as well as the computational power at user’s computer).

This includes processing the CAD geometry, setting up the symmetry boundary conditions for accurate replication, and adjusting parameters for optimal hardening.

Here’s how the simulation is set up for this particular case study

The software offers engineers the flexibility to simulate with varied parameters like power, frequency, and scanning speed, and do that multiple times within a single day. In one test case, a shaft with 18 splines was simplified by creating a half-shaft model, which significantly reduced calculation time without sacrificing accuracy.

The simulation even incorporates differential heat transfer rates for the heating and cooling sections, allowing precise control with coefficients such as 5 W/(m²·K) (which describes the natural convection process) for heating and 100 W/(m²·K) (which describes spray-showering with given parameters) for cooling.

What can engineers read from the simulation?

- Temperature gradient

The simulation shows a clear progression of temperature from the heated section (red) to the cooler areas (blue). This gradient indicates how effectively the heat is applied and dissipated.

- Cooling dynamics

The transition from red to blue near the cooling zone shows the efficiency of the cooling system (e.g., spray showers). Engineers can analyze the rate at which the material cools and ensure it aligns with the desired hardening process.

- Symmetry and uniformity

The symmetrical heat distribution around the shaft can be evaluated to ensure uniform hardening. Any anomalies in the heat profile could indicate design issues with the inductor or cooling system.

What kind of decisions can be made?

- Hardness profile prediction

The temperature distribution can help engineers predict the resulting hardness profile of the shaft. Regions heated to a specific range are expected to harden to a particular depth and hardness level.

- Optimization of parameters

Engineers can use this simulation to fine-tune parameters such as power, frequency, and scanning speed. For instance, ensuring the red zone reaches the desired temperature quickly while maintaining uniformity.

- Energy efficiency assessment

The efficiency of energy transfer from the inductor to the shaft can be analyzed. Engineers can identify areas where heat is lost or unevenly distributed, enabling improvements to the process.

- Cooling system effectiveness

The rapid shift in temperature near the cooling zone can be used to assess the cooling system’s performance. Engineers might analyze whether the spray shower or other cooling mechanisms are optimally positioned and effective.

- Material behavior

The simulation can show how different materials react to the induction heating and cooling process. This is particularly useful when selecting materials for specific applications.

- Process validation

Comparing simulation results to experimental data validates the process, reducing the need for costly physical prototyping.

The power of CENOS lies not only in saving time but also in enabling engineers to keep within available power supply limits by defining voltage and current sources for each setup. This control ultimately makes sure that each process stays efficient, reliable, and within budget.

The light-colored section of the shaft represents the hardened region, showing the area affected by the induction heating process. This visualization allows engineers to verify whether the hardening is uniform and meets the desired specifications.

Engineers can assess whether the hardened area matches the required depth and shape based on the operational parameters. This is critical for ensuring mechanical properties such as strength and wear resistance.

- Magnetic field lines

The blue lines depict the magnetic field generated by the induction coil. These lines demonstrate how the magnetic field interacts with the shaft, showing areas of higher field density where energy transfer is most concentrated.

- Field intensity distribution

The density of the magnetic field lines near the coil indicates regions of higher magnetic field intensity, which correlates directly with heat generation in the shaft. This information is vital for ensuring the hardening process is uniform.

- Inductor design

The orange-colored induction coil shows how the coil geometry affects the magnetic field distribution. Engineers can assess whether the coil design is optimal for uniform heating of the shaft.

- Field interaction with the shaft

The magnetic field’s penetration into the shaft material is visible. This determines the depth of heating and, consequently, the depth of hardening.

What is the result?

With CENOS simulation software, the induction scanning and hardening process of a shaft can be fine-tuned to perfection. And it can be done within hours rather than weeks. Engineers gain immediate insights into the hardness profile achieved at specific operating parameters.

For instance, using a two-turn inductor with a flux concentrator, one simulation produced a precise hardening profile after just 15 seconds of heating at 10 kHz, 6 kA, and 10 mm/s scanning speed. This level of control not only accelerates the prototyping phase but also ensures that manufacturers produce higher-quality components with minimal waste.

In this particular simulation we see the following results from these graphs:

- Active power

The graph shows total power stabilizing around 10.5 kW, with the workpiece consuming approximately 5 kW and the inductor around 5.5 kW. We see that each inductor (and we have 2) consumes just below 6 kW, and so does the workpiece, which makes resulting efficiency just around 33%, which is not very good. This shows efficient energy transfer to the workpiece, as total power closely aligns with the sum of individual components. Engineers can use these values to pinpoint where energy losses may occur.

- Inductance

Inductance fluctuates between 13 nH and 17 nH for different terminals during the process. Terminal 1 peaks at 17 nH, while Terminal 11 stabilizes near 13 nH after 1 second. These shifts show varying electromagnetic coupling, helping engineers assess coil design and material behavior during heating.

- Current amplitude

The current amplitude stabilizes near 8 kA for Terminal 1 and fluctuates slightly after 2 seconds, remaining within ±0.5 kA. This steady current ensures consistent heating. Engineers can monitor these values to maintain process stability and avoid overheating.

- Voltage amplitude

Voltage amplitude rises quickly to about 16 V for Terminal 1 and stabilizes around 14 V after 1 second. Terminal 11 follows a similar trend but stabilizes closer to 12 V. These consistent voltage levels confirm stable energy transfer and reliable power delivery for the process.

For engineers, this case shows how using a simulation software can transform the hardening process, reducing material waste, saving time, and improving process efficiency. As industries push for greater sustainability and faster time-to-market, a proper simulation software bring precision and power to their design and production workflows.