Induction heating in the railway & subway industry

The unrivaled accuracy, control, and efficiency of induction heating makes it ideal for key tasks in the manufacture and maintenance of rolling stock and rails. These involve custom-designed induction heating and hardening processes, developed by engineers with the help of a variety of tools, including the simulation software.

Induction shrink fitting – removal and installation of bearings, wheels and other drive components

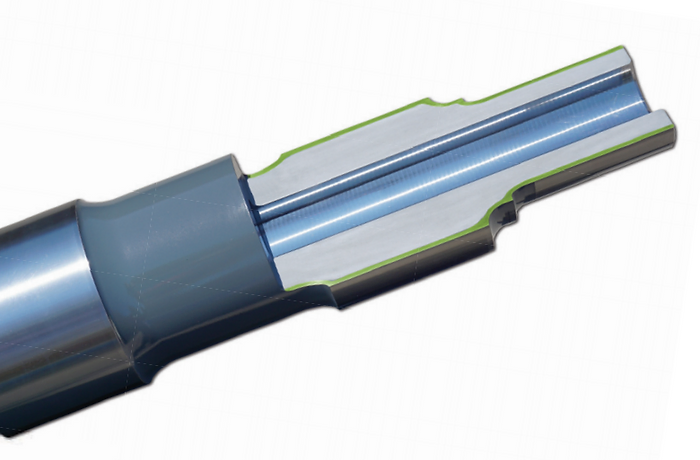

For removing and installing railway bearing sets and labyrinth rings, gears, brake discs, bearing inner rings etc., special induction heaters are used together with hydraulic pullers.

Image courtesy – EFD Induction

Middle-frequency induction heating is a safe and cost-effective heating method that improves the quality of the installation, using modified induction coils, the bearings and labyrinth seals can be quickly brought up to the required temperature in a controlled manner so that the crimp connection comes free. In the contrary – when removed mechanically it always results in damage that requires repairing and therefore extra time and costs. Compared to traditional methods of heating, induction technology is a much faster and more efficient heating process, making it the preferred choice for lead players in the railway industry.

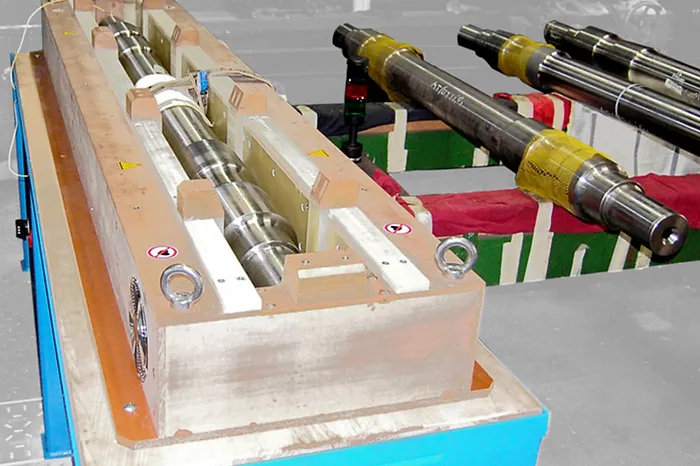

Wheelset shaft coating

Image courtesy – RITER Induction

Before train wheel shafts are assembled with components such as bearings, wheels, brake discs, drive assemblies, etc, they are treated with a molybdenum protective layer. This is to protect them against premature wear. In order to prepare the shafts properly for this process, they are heated by induction in order to improve adhesion and to guarantee a longer life of the protective layer. The technique and systems are mainly used by wheelset manufacturers and maintenance and reconditioning companies in the rail industry.

Train wheel maintenance

The overhaul of train wheels and wheel rims presents the challenge of first removing and then refitting later on.

The mono-block (solid) wheels are heated from -30°C to 20°C ambient temperature on specially designed induction benches so that the wheels can be worked on and rotated with the correct dimensions.

Induction hardening of rollbocks, axles, disk breaks and rails

Induction hardening is applied to the surface of rollbocks – to prevent deterioration of the rolling contact area between the train wheel and the rail. Also train disk breaks are hardened with induction.

Induction-hardened axles – a modern solution to the requirements of increased safety and reliability. It also brings a significant decrease in life-cycle costs.

BONAXLE® brings paradigmatic change in railways

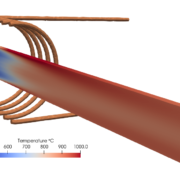

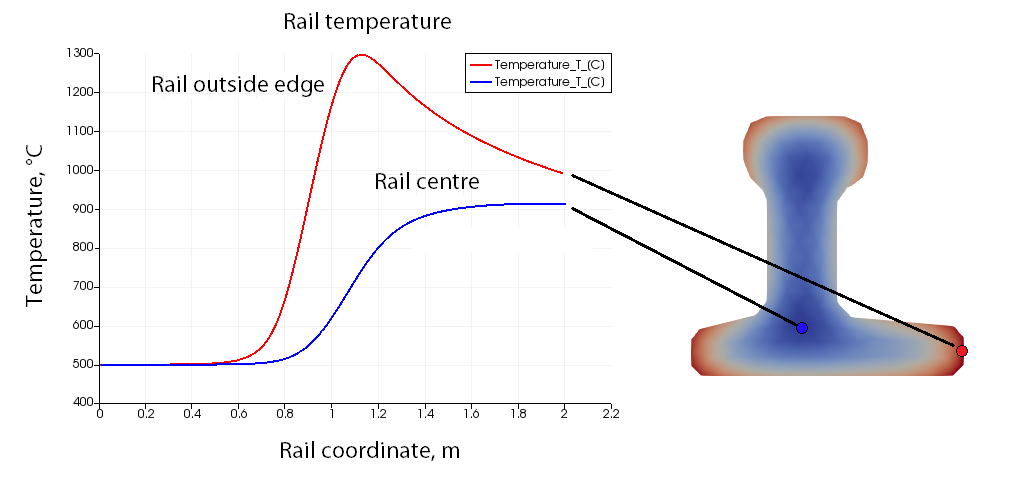

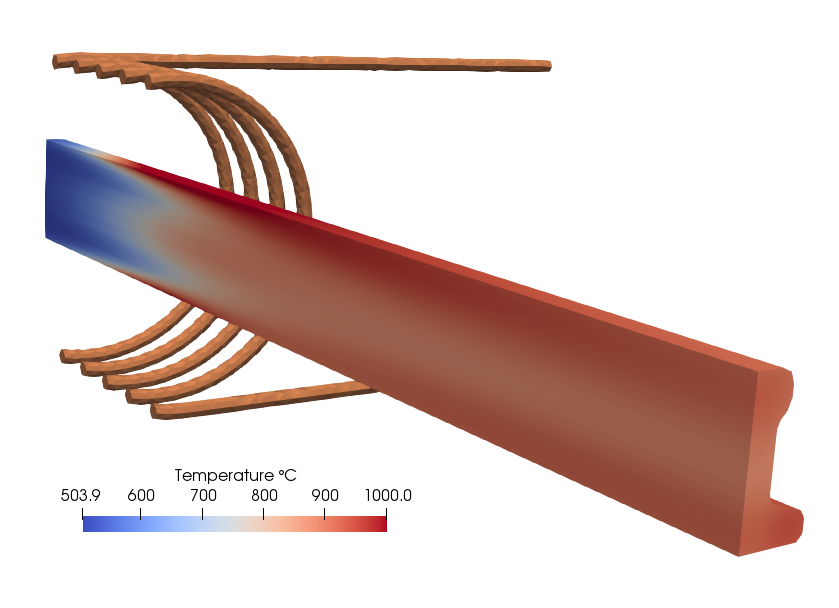

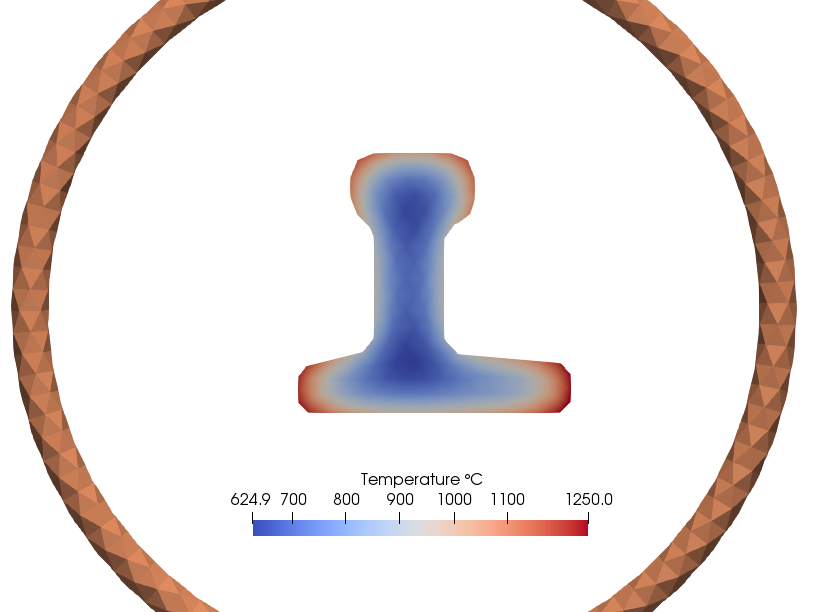

Rails – rail hardening systems utilize induction heating to effectively harden rails. To optimize heat treatment results – power and frequency must be effectively controlled to homogenize the temperature over the length of the rail.

Another important component of railway systems – switch blade heads are induction hardened and normalized to guarantee longevity.

In addition of heat treating, other applications for induction heating in both rolling stock and infrastructure manufacturing include axle heating and straightening of body panels.

Rolling stock applications

- Diesel Motor: parts heat treatment

- Electrical Motor: short circuit ring brazing, rotor shrink fitting

- Rail Vehicle Body: plate straightening, paint removing

- Suspension: leaf spring end heating

- Shaft: molybdenum coating

- Wheelset: wheel shrink fitting

- Brake system: disk brake hardening

Railway maintenance applications

Motor repairing

Wheel band shrink fitting

Spare parts heat treating

Rail infrastructure applications

- Clips forging

- Fasteners thread forging

- Rail forging

- Head rail hardening

- Rail normalising

CENOS induction heating 3D simulation software can help engineers to develop the hardening process of various railway components.

If your company represents or does jobs for the railway industry, call or write us – our engineers would be happy to learn more about your induction needs and discuss how our software could potentially save your valuable hours spent on induction process and coil design.