Importance of heating simulations for additive manufacturing coils

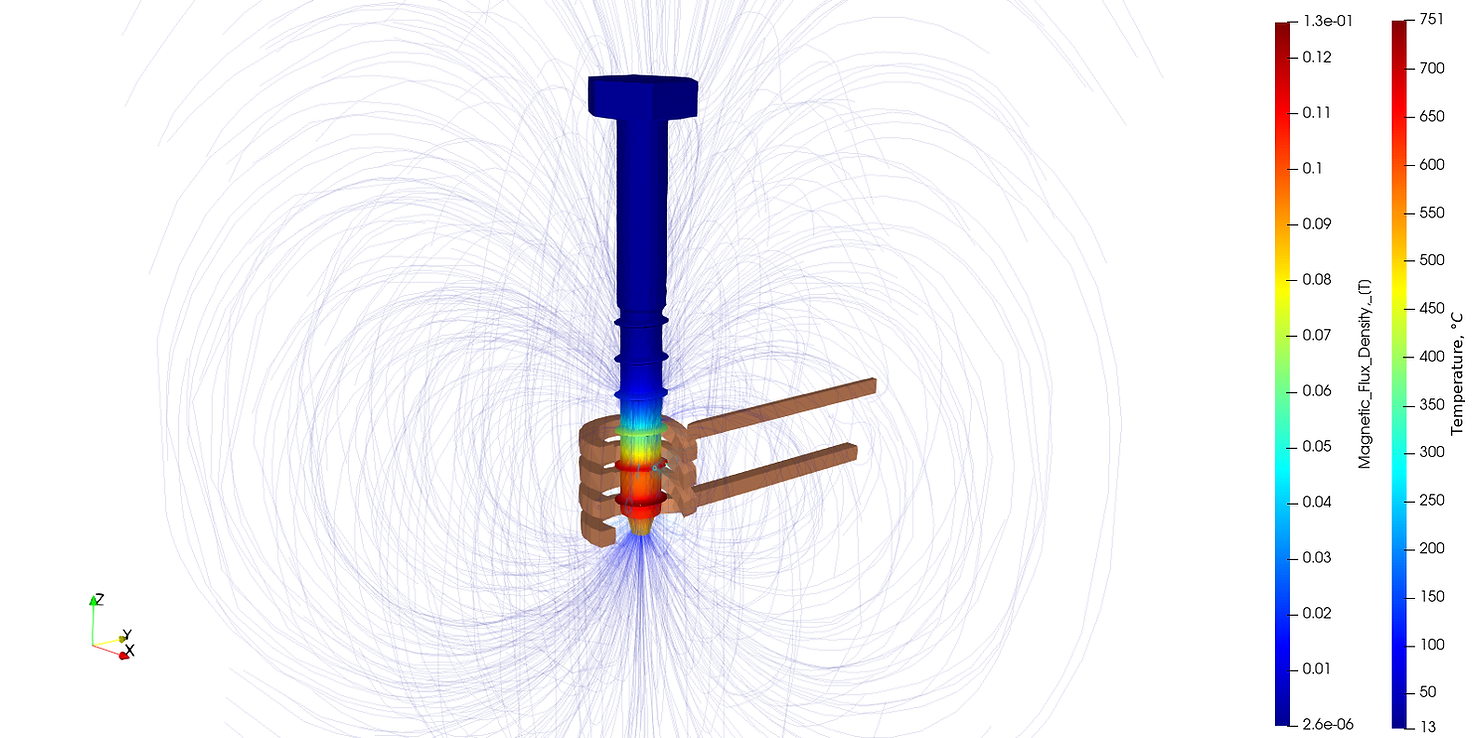

Additive manufacturing can be a cost-effective way to produce inductor coils, but the slow printing process can hinder development. Induction heating simulations can provide a fully digital development process, saving time and resources while detecting issues with heat distribution and preventing undesired effects. This combination offers a promising solution for inductor coil production.

Himmelwerk faced a problem with the slow turnaround time for the 3D printing process in their inductor coil production. This meant that mistakes in the design or the need for several iterations resulted in long waiting times.

Himmelwerk faced a problem with the slow turnaround time for the 3D printing process in their inductor coil production. This meant that mistakes in the design or the need for several iterations resulted in long waiting times.

As a small boutique manufacturer, the cost of induction simulation software for big companies like the aerospace industry or automakers was impossible to bear. With only one engineer working on the simulations, there was no room to pay tens of thousands of euros every month for the tools for a single employee.

To solve this problem, Himmelwerk turned to CENOS, which offered affordable prices for small use-case companies like theirs. With CENOS™ simulation software, their engineer could test out different coil designs and account for different workpiece or insulation materials and configurations without going through printing a new prototype every time.

The development process became fully digital, and when the first prototype was printed, it was usually also the last. This saved precious time and resources and freed the printer up for actual production.

Himmelwerk would not have succeeded without CENOS™ simulation software because the cost of induction simulation software for big companies was too high for a small boutique manufacturer like them. CENOS™ simulation software offered affordable prices for small use case companies like Himmelwerk, which allowed them to use induction simulations.

This was especially important for 3D printing, where the payoff was easily visible. The simulations allowed Himmelwerk to get additional readings from inside a workpiece, run tests on workpieces that were too big or too heavy for their application lab in Tübingen, and improve quality guarantees for all their products.

This was especially important for 3D printing, where the payoff was easily visible. The simulations allowed Himmelwerk to get additional readings from inside a workpiece, run tests on workpieces that were too big or too heavy for their application lab in Tübingen, and improve quality guarantees for all their products.

Himmelwerk praised the simulation software because of their fast implementation of customer feedback into their product and their rapid iteration of software features. CENOS was also helpful with the occasional troubleshooting that comes with all software.

Their engineer was especially happy with how fast the simulation software was adding new features all the time.

According to Himmelwerk:

“CENOS™ simulation software has been a great partner for us ever since getting into simulations for the first time all those years ago. They steered us towards a better choice of workstation for our needs, were available in real time or through mail within hours whenever we needed them.”

It’s always great to hear positive feedback from our clients, and we strive to continue providing top-notch service and support.