How to use FreeCAD and CENOS simulation to improve surface hardening for vice components

Let’s dive into creating precision mechanical parts, like vice base. It’s quite a popular tool. Anyone with a proper garage in their house and a DIY attitude probably has one. But industry-level vices are much bigger and more complex. We all know they need to be really tough on the surface to handle constant wear and tear. And we want the vice to last for a long time and not wear out with some tough work.

To make the vice parts tough, a usual hardening process is necessary. Getting the heat treatment just right can be tricky. Usually, it takes a lot of testing, trial and error, and plenty of expensive prototypes to get things perfect.

But there’s also a simpler way. Using induction heating simulation, engineers can easily test and optimize how well a vice component will harden, all from their computer screen. Long before any prototypes are built. Engineers can improve the design and run as many tests needed until the perfect design is available.

Let’s see how this works.

Using FreeCAD with CENOS

Using simulation is simpler than you think. We have recently talked with Aleksander Sadowski. Turns out he’s a true FreeCAD enthusiast who designed a simple vice model, and he was particularly interested in using a simulation software to test that design and improve it. (He’s also doing FreeCAD training for engineers: alsado.de).

Why FreeCAD?

This is a widely known design tool that is fully compatible with CENOS. Just import the FreeCAD design to CENOS, set up the parameters, and run the simulation. So we combined drawing in FreeCAD and CENOS and got the results.

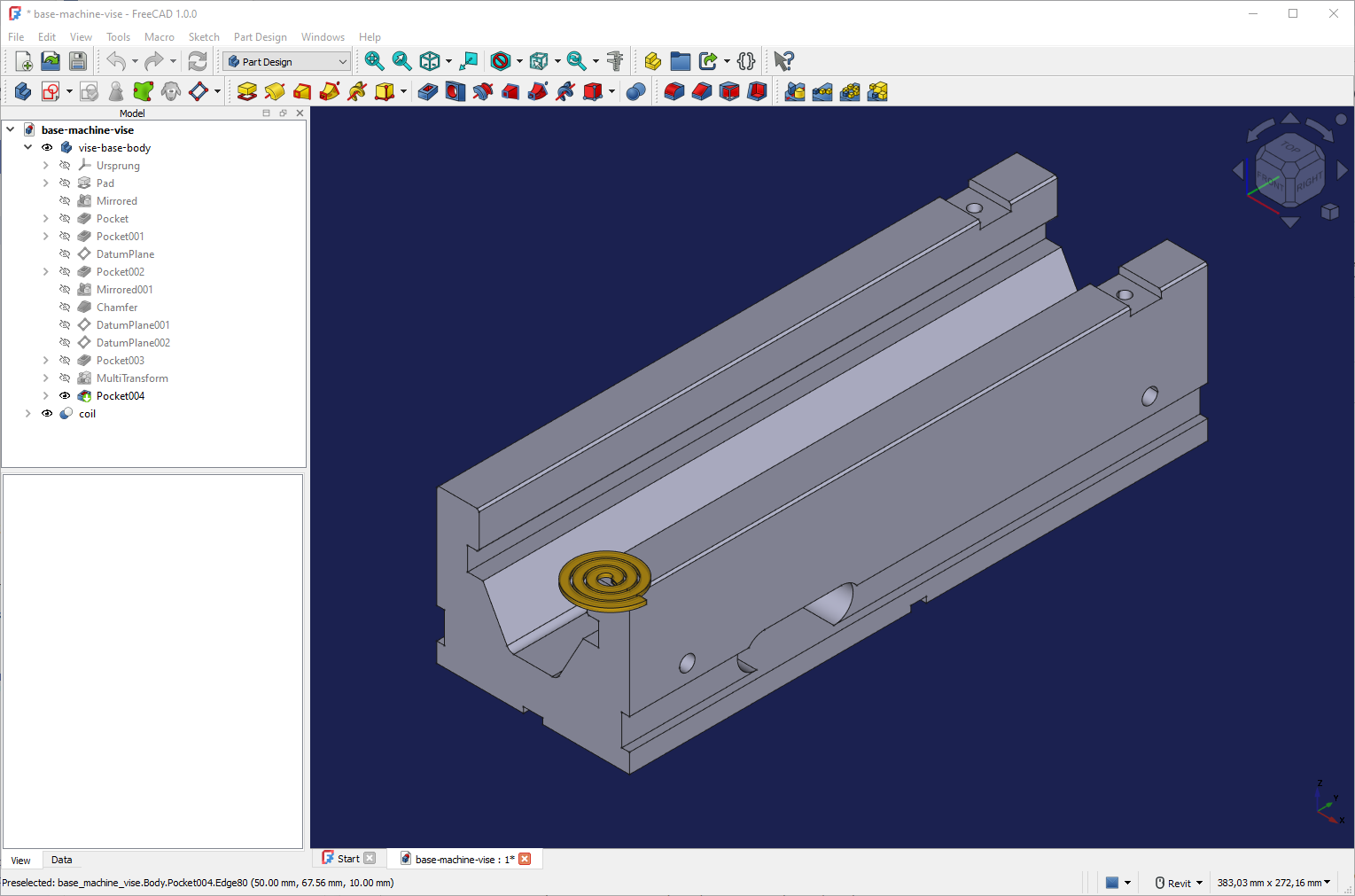

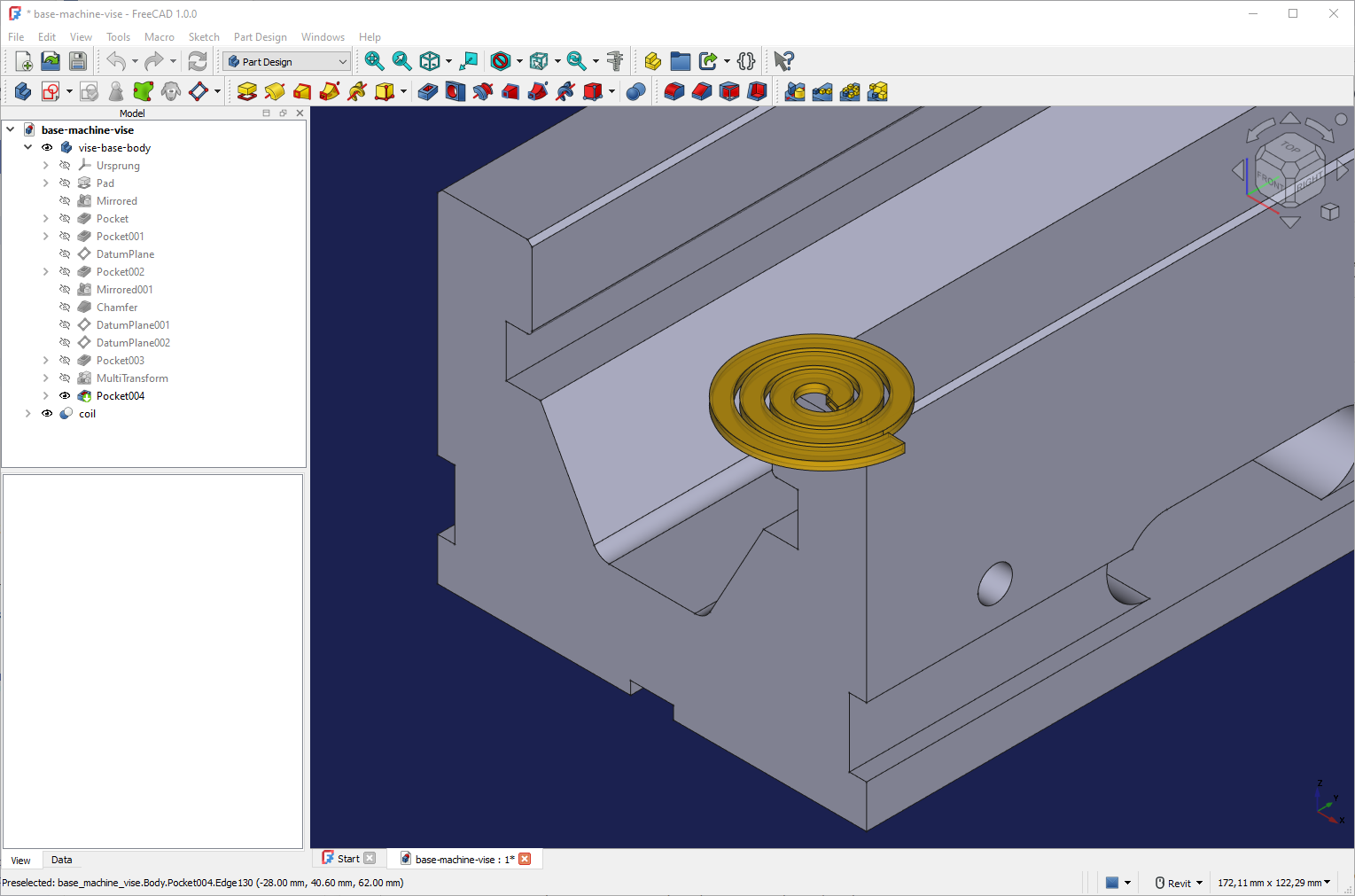

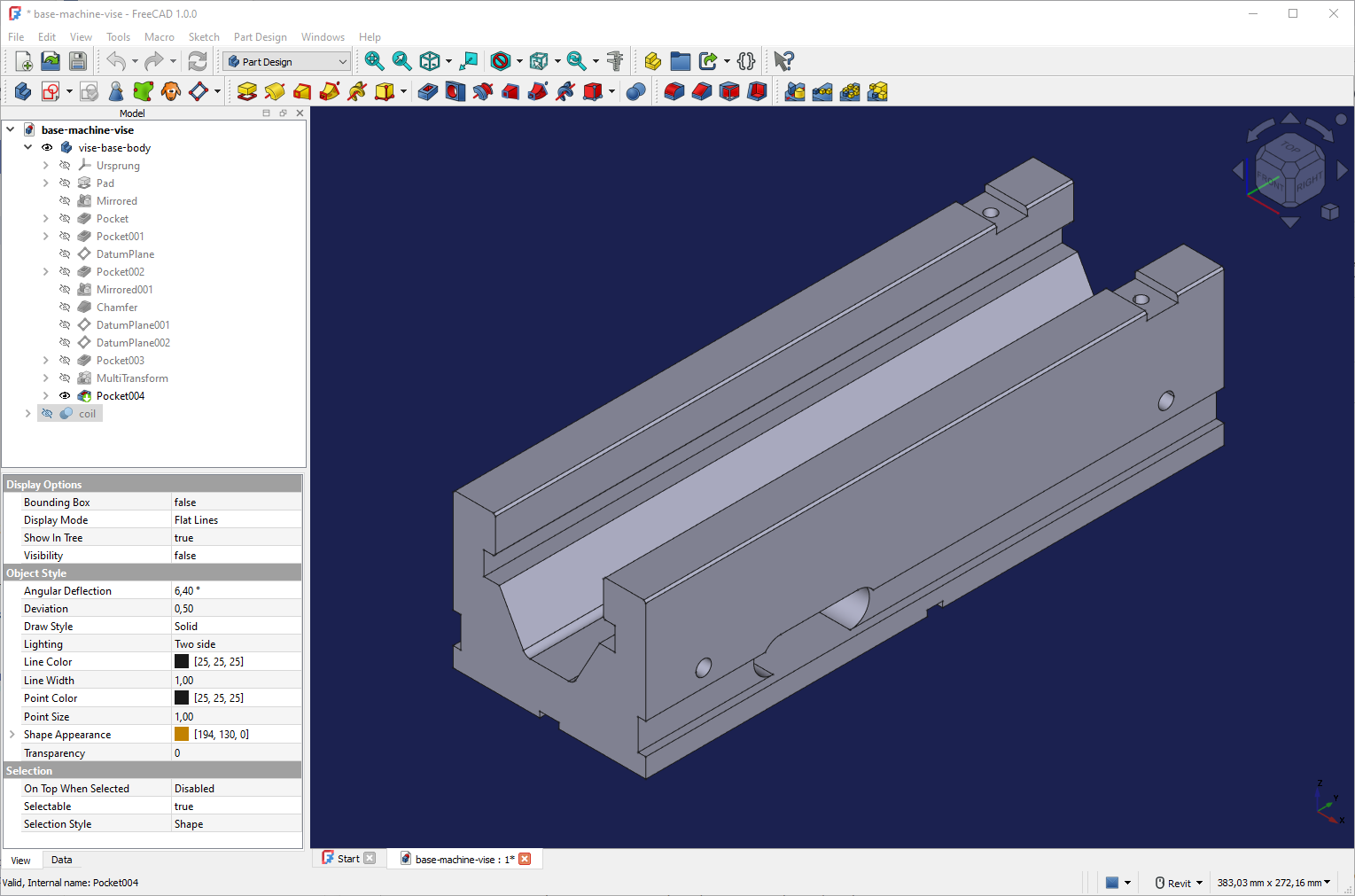

Here, we can see how the model was created in FreeCAD.

Making a vice that’s tough enough to withstand heavy use is tricky. The challenge is getting an even, reliable hardness on the surface. Traditionally, engineers had to guess and test repeatedly, wasting time and money on prototypes. It’s slow, costly, and there’s always a risk the final product won’t be as good as expected.

One of the biggest advantages of FreeCAD is its excellent compatibility with simulation software like CENOS. Engineers can easily import their FreeCAD models directly into CENOS, set simulation parameters, and quickly start running tests digitally without needing physical prototypes first.

Now that the design of a vice part is ready we can test it with simulation tool.

Running a simulation

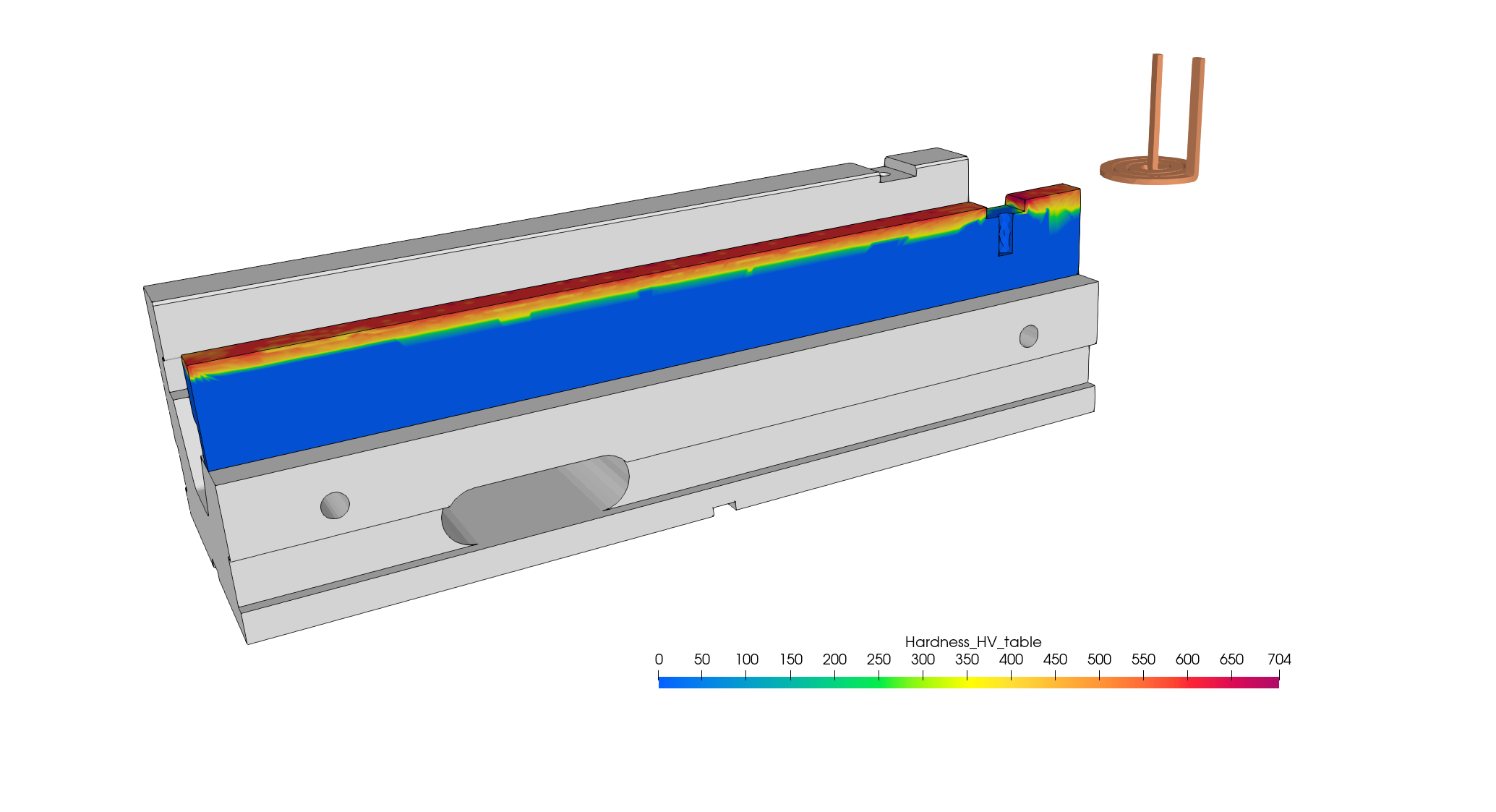

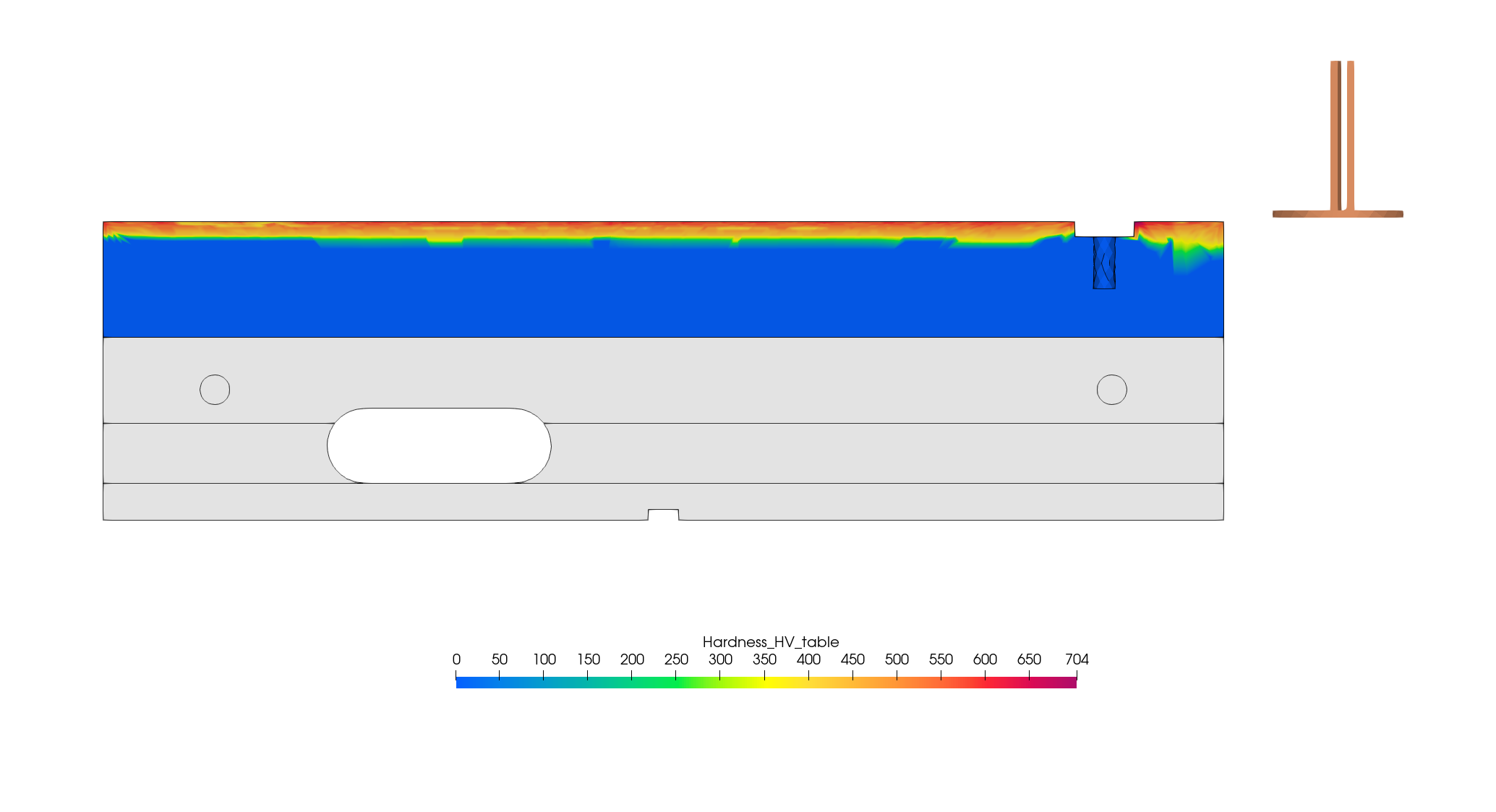

Using induction heating simulation software, engineers can visualize exactly how heat will affect the vice component before making any physical parts. Here you can see couple of snapshots from the simulation software according to these FreeCAD designs we presented before.

The images show how the simulation reveals the hardness across the vice part. The colors show hardness levels measured in HV (Vickers Hardness). Bright reds and purples show areas with the highest hardness, which are perfect for surface durability. The blues are softer areas, meaning the heat didn’t reach deep into the metal, keeping the internal structure strong and flexible. Green and yellow colors show a gradual change between these extremes, confirming smooth transitions.

An additional feature in this simulation is that engineers can also include cooling. In the simulation animation below, you can see how cooling follows immediately after the induction coil moves over the part. This helps engineers control the hardening process precisely and prevents overheating or unwanted distortion.

What is the result?

Using simulation software, engineers find the best induction heating setup without building multiple prototypes. You can use the FreeCAD design tool to test and improve your designs using CENOS simulation software. FreeCAD is widely known and used amongst engineers, fully compatible with CENOS.

This digital-first approach speeds up the entire design process, reduces costs, and makes sure that you will produce consistent, high-quality vice parts every single time. Engineers can confidently move forward with production, knowing exactly what they’ll get. No surprises, no wasted effort.