Manual meshing tips & tricks

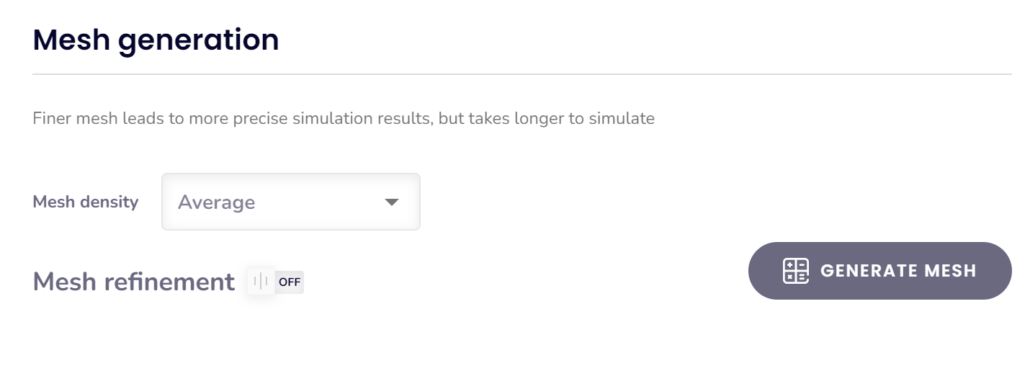

When you reach the meshing stage in CENOS for the first time, you will encounter a window that looks like this:

- You can generate the mesh automatically, review it to determine if it meets your requirements, and then make manual adjustments as needed.

- Alternatively, you can enable Mesh Refinements beforehand to customize the mesh parameters prior to generation. However, we recommend starting with an automatically generated mesh and then refining it as needed.

Automatic mesh generation

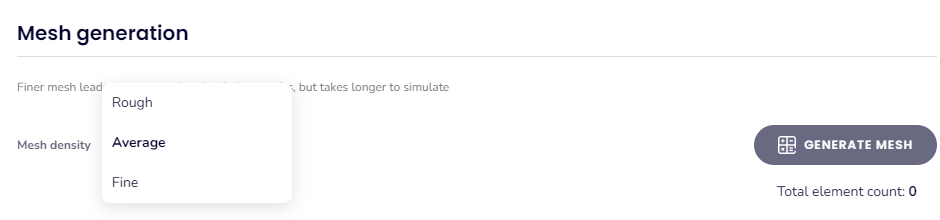

You can choose between three mesh densities — Rough, Average, and Fine — depending on the level of detail required for your analysis. To create the mesh, simply click on GENERATE MESH, and the software will generate it automatically based on your selected density.

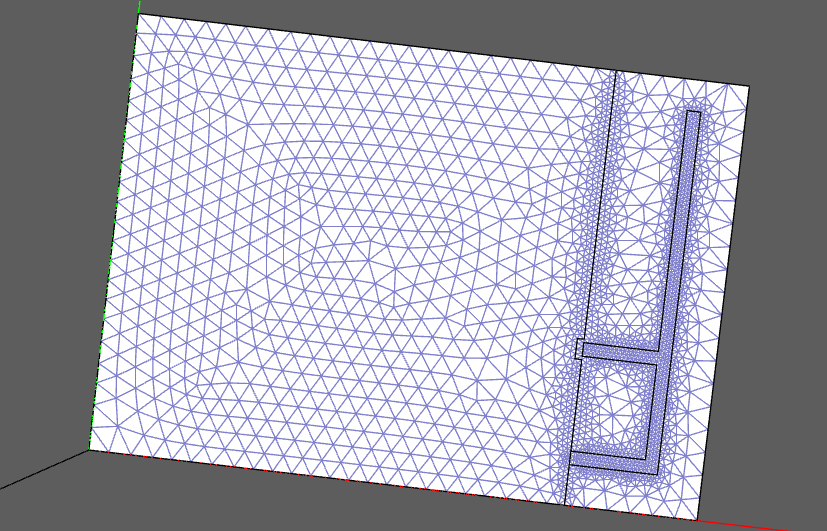

The automatically generated mesh includes built-in refinements based on your model’s geometry, helping to streamline the simulation process and improve overall accuracy without requiring additional setup.

Manual refinements overview

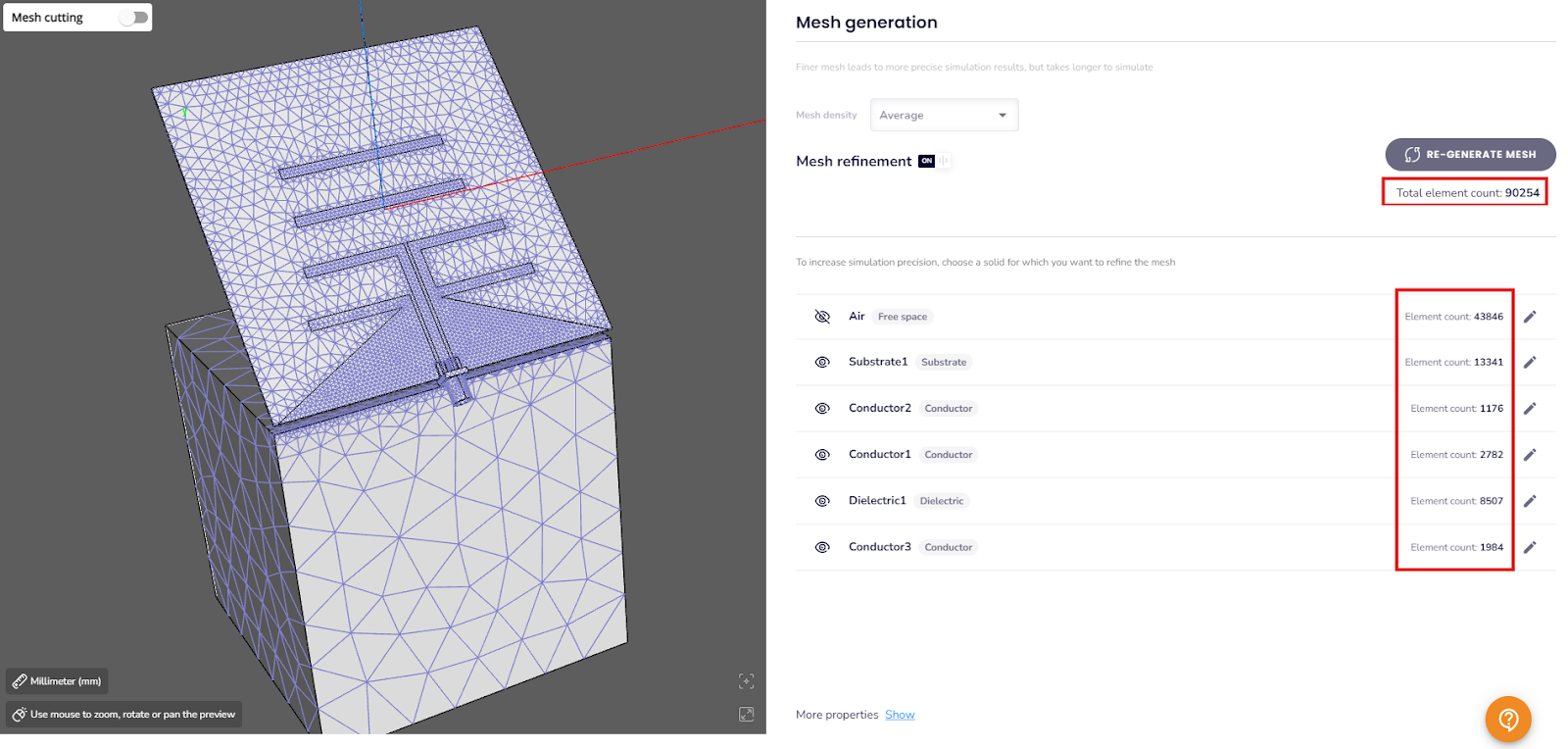

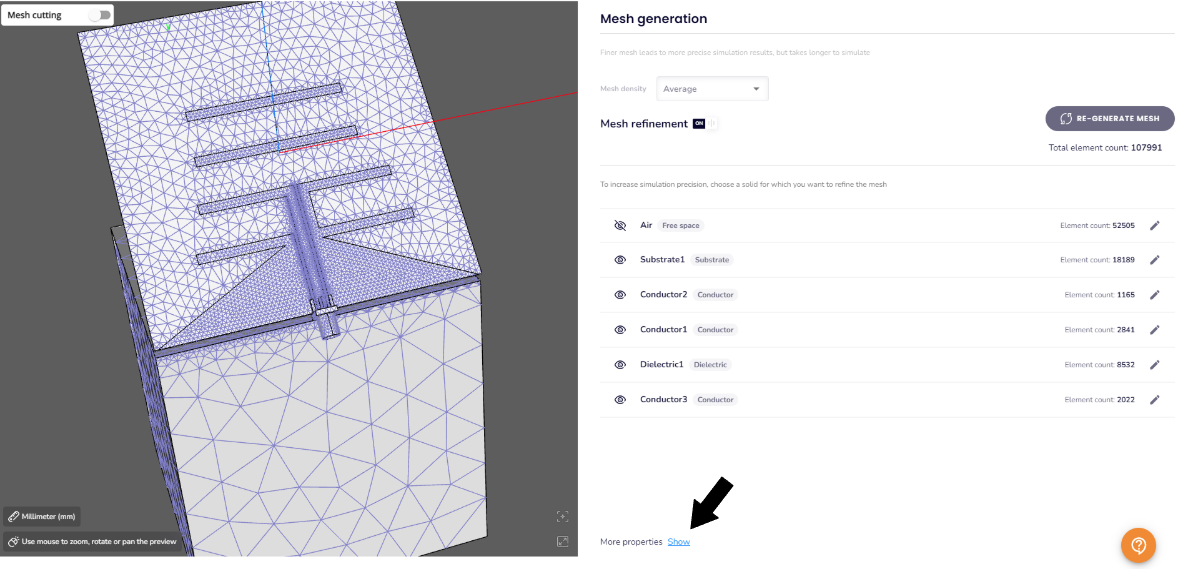

For the purpose of example on how to adjust the mesh manually we will start with automatic mesh generation. When it is done, you will see the total element count and element count in each domain.

Manual meshing for a specific domain

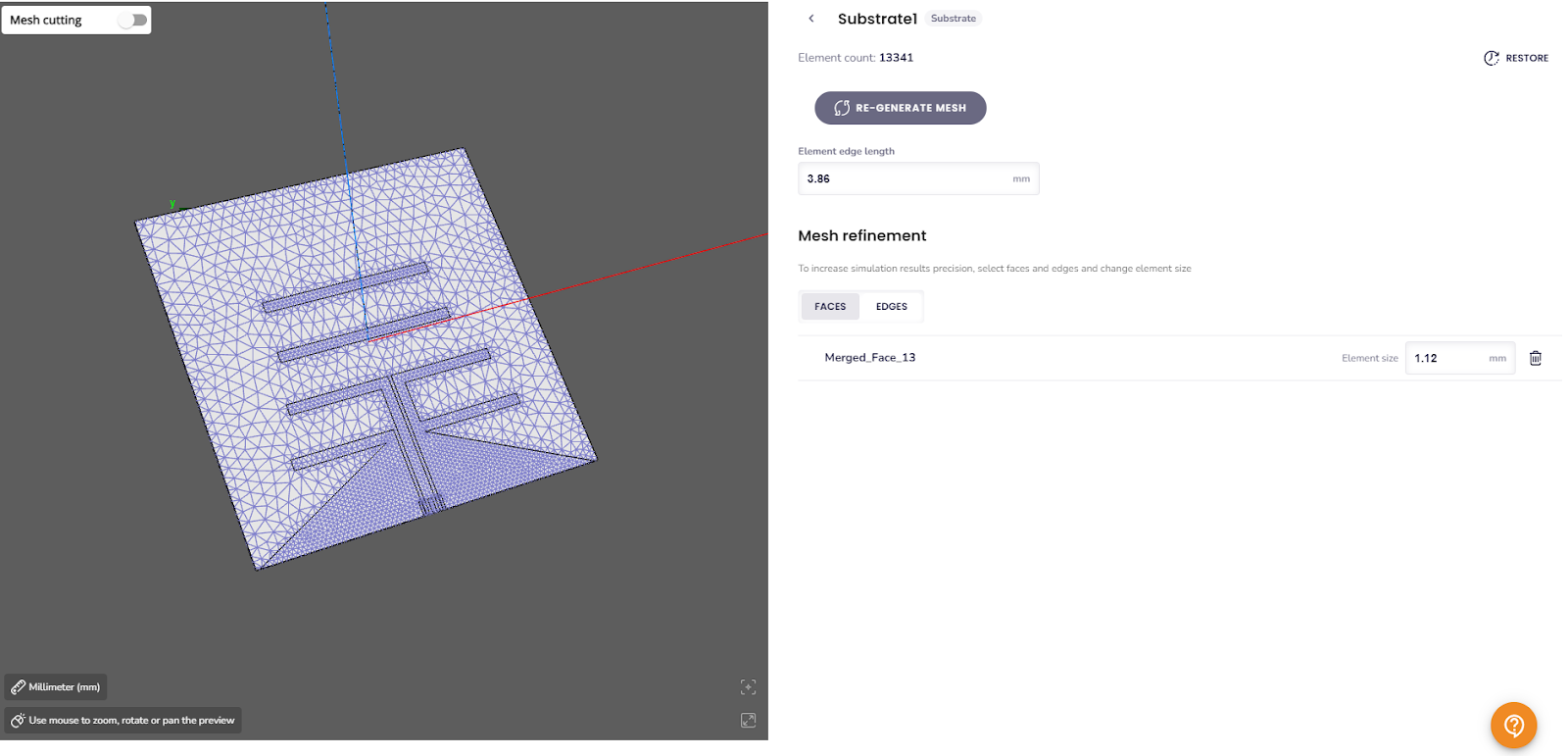

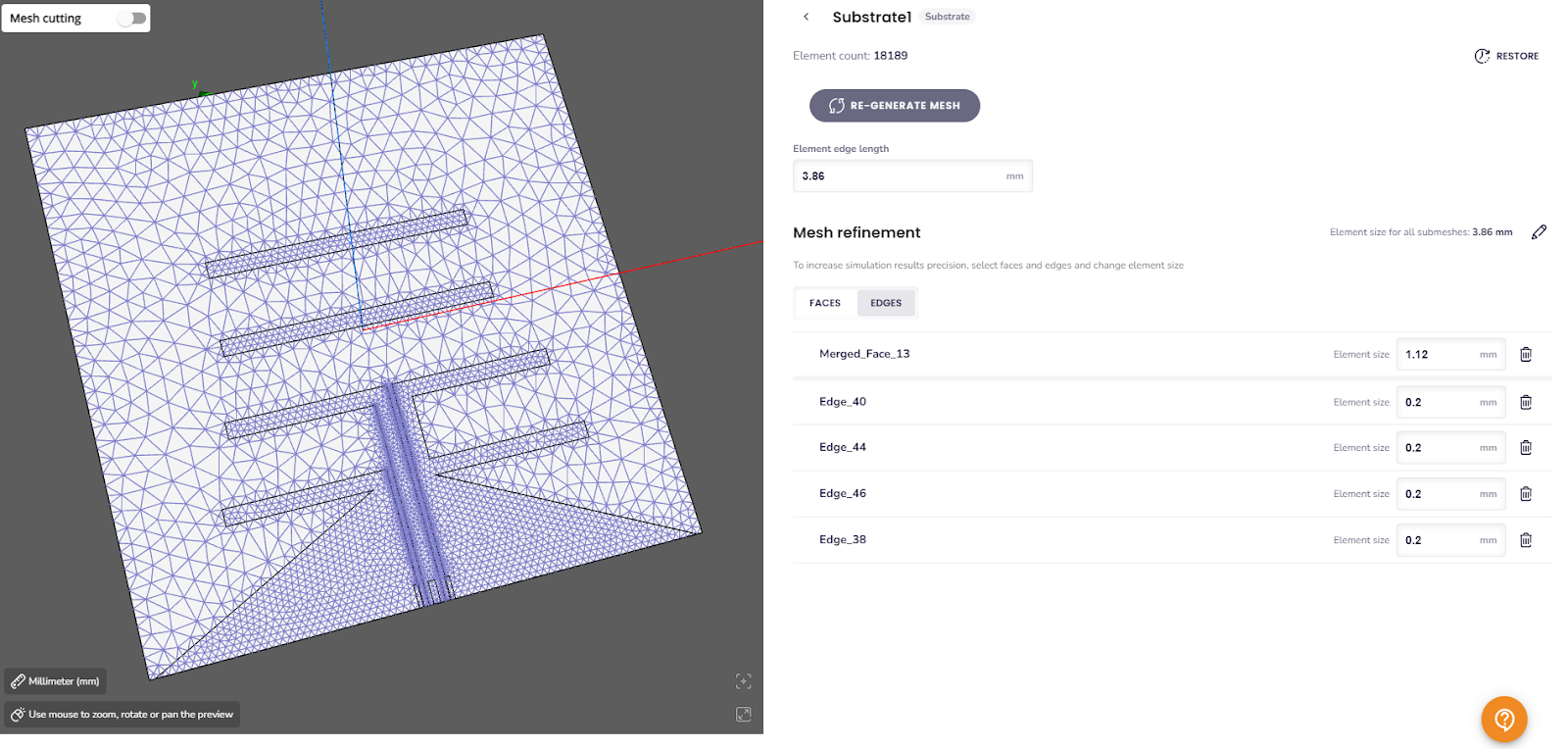

To refine the mesh for a specific domain, click on the domain to open a dedicated window for mesh adjustments. For instance, selecting the Substrate will open the Substrate meshing window, where you can tailor the mesh settings for that object.

When refining the mesh of a specific domain, you have access to several tools and customization options to optimize the mesh for your requirements.

Face / Edge Refinements:

Fine-tune the mesh on specific faces or edges within the domain for increased resolution. To do the refinement of a face, just hover over it and you will see how it is highlighted. The same goes for edge refinement, just make sure you are in the EDGES tab.

- Useful in regions where greater accuracy is required for determining the electromagnetic field.

Global mesh parameters

You can also modify global mesh parameters, which will apply to all domains. These settings are located under the “More properties” section at the bottom of the meshing window.

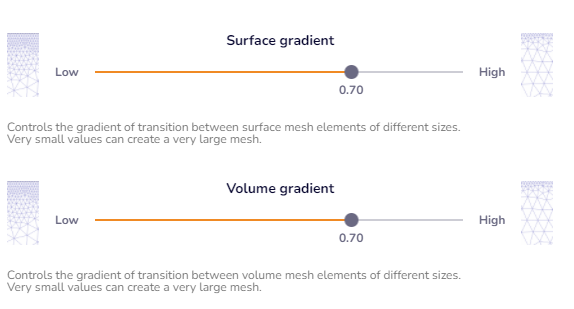

Volume & Surface gradients

Volume and surface gradients control the rate of transition from smaller to larger volume or surface elements in the mesh.

- Lower Gradient Values: Result in a more uniform mesh with less variation in element size but generally lead to a denser mesh. This is useful for improving accuracy in regions where high precision is required, but it will increase calculation time as well.

- Higher Gradient Values: Allow for a coarser mesh with fewer elements by permitting greater variation in element size. This can optimize computational resources and reduce simulation time.

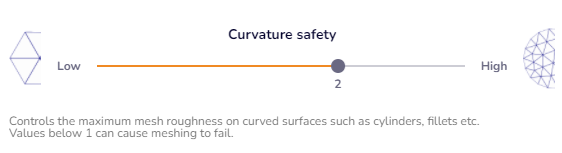

Curvature safety

For geometries with curved features (e.g., wire antennas, coaxial connectors), adjusting the curvature safety parameter can be helpful:

- Increase Curvature Safety: Improves mesh resolution for domains with rounded shapes, ensuring better accuracy in capturing curvature details. This is useful if the current mesh appears insufficiently refined in curved areas.

- Decrease Curvature Safety: Reduces mesh density in curved regions, optimizing element count and computational efficiency if the mesh is unnecessarily dense.

This adjustment ensures the mesh is appropriately refined to balance accuracy and resource use in curved geometries.

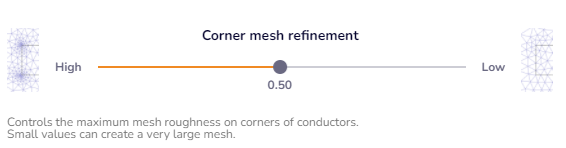

Corner mesh refinement

For geometries with sharp edges or pronounced corners (e.g., patch antennas, traces), enabling corner mesh refinement can significantly improve simulation accuracy:

- Increase Corner Refinement: Increases mesh resolution near sharp corners and edges, capturing field variations more accurately in regions with high field gradients.

- Decrease Corner Refinement: Reduces mesh density around corners, helping to optimize the overall mesh size and computational load when corner detail is less critical.

This setting helps ensure that the mesh is sufficiently refined around geometric discontinuities, balancing precision and computational efficiency.

Tips and tricks

In some cases, an automatically generated mesh may be excessively dense, making it impractical due to high computational resource demands. Here are steps you can take to reduce the mesh element count effectively:

- Increase the Element Edge Length in Select Domains:

- For domains where high precision is less critical (e.g., substrates or enclusures), increase the element edge length.

- Adjust the Surface Gradient:

- Start by increasing the surface gradient from the default value of 0.7 to 0.85.

- This reduces overall mesh while maintaining reasonable accuracy.

- Reduce the Curvature Safety:

- Lower the curvature safety from 2.0 to 1.5, or try even smaller values like 1.1 (this reduces the mesh resolution around curved geometries and helps minimize the element count further).

- Increase the Corner Refinement:

- Increase the corner refinement from 0.5 to 0.8, or try even higher values if needed, lower values can lead to finer mesh near sharp edges, significantly increasing the total element count.

- Regenerate the mesh:

- After making these adjustments, regenerate the mesh to evaluate the impact of the changes.