Catheter tipping case study: making better medical devices

Medicine has been around for thousands of years. There are new inventions and improvements to help people live healthier and longer lives. In this case study, we will look into the induction heating (also rf induction heating) of a catheter with CENOS simulation software.

Catheters, specifically, have a long history. They’ve been used since ancient times, with early examples dating back to around 3000 BCE. Over the centuries, they’ve transformed from simple tubes made of reeds or metal into medical devices designed for precision and patient comfort.

In this case study, we dive into how induction heating simulation can further improve catheters, making them safer and more reliable for patients and medical device manufacturers.

What’s the challenge?

When making catheters, internal stress can build up inside the material. This stress makes the catheter brittle, which is a big problem. It can cause the device to crack or break when pressure is applied during use. And we don’t want this to happen. This is especially important for the tip because it has to be sharp enough to pierce the skin but still flexible enough along the rest of the length not to break.

Typically, manufacturers use trial and error to solve this problem, creating lots of prototypes. It takes time and can get expensive fast. However, using modern simulation tools can speed things up and simplify the entire process. And this is exactly what we are going to do now.

RF induction heating simulation of a catheter tipping

RF induction heating is a smart way to control exactly how a catheter is heated, using electromagnetic fields. By carefully controlling the heat, we can reduce the internal stresses without weakening the catheter.

In our simulation, we fine-tuned exactly where and how much heat was applied by adjusting the induction coil’s length and position. We aimed most of the heat at the middle section, with just enough heat reaching the tip to keep it strong but not brittle.

Inside the simulation:

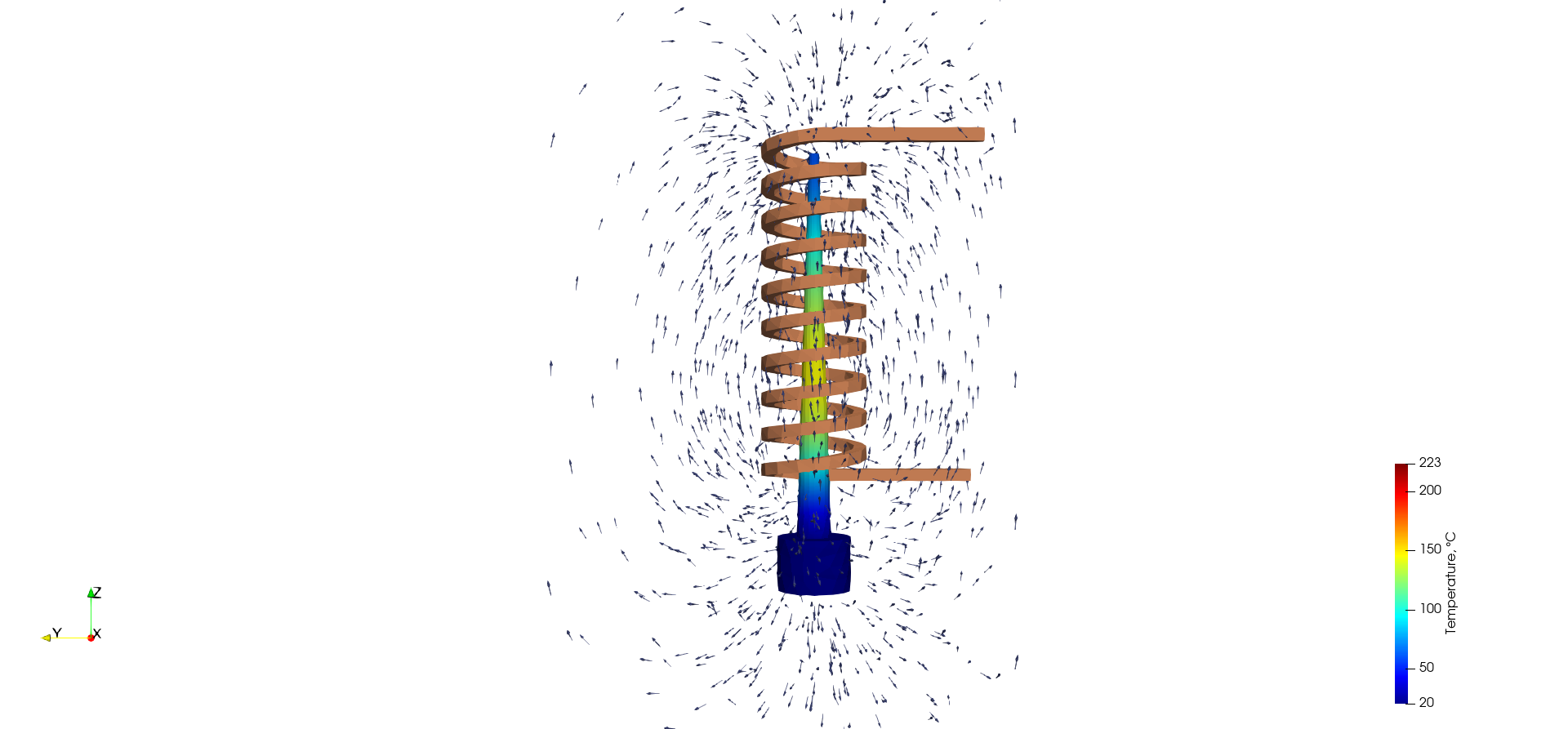

- Image 1: Shows the initial setup with the induction coil around the catheter. You can clearly see where the electromagnetic field is strongest—right around the catheter’s center. This helps achieve exactly the heating profile we need.

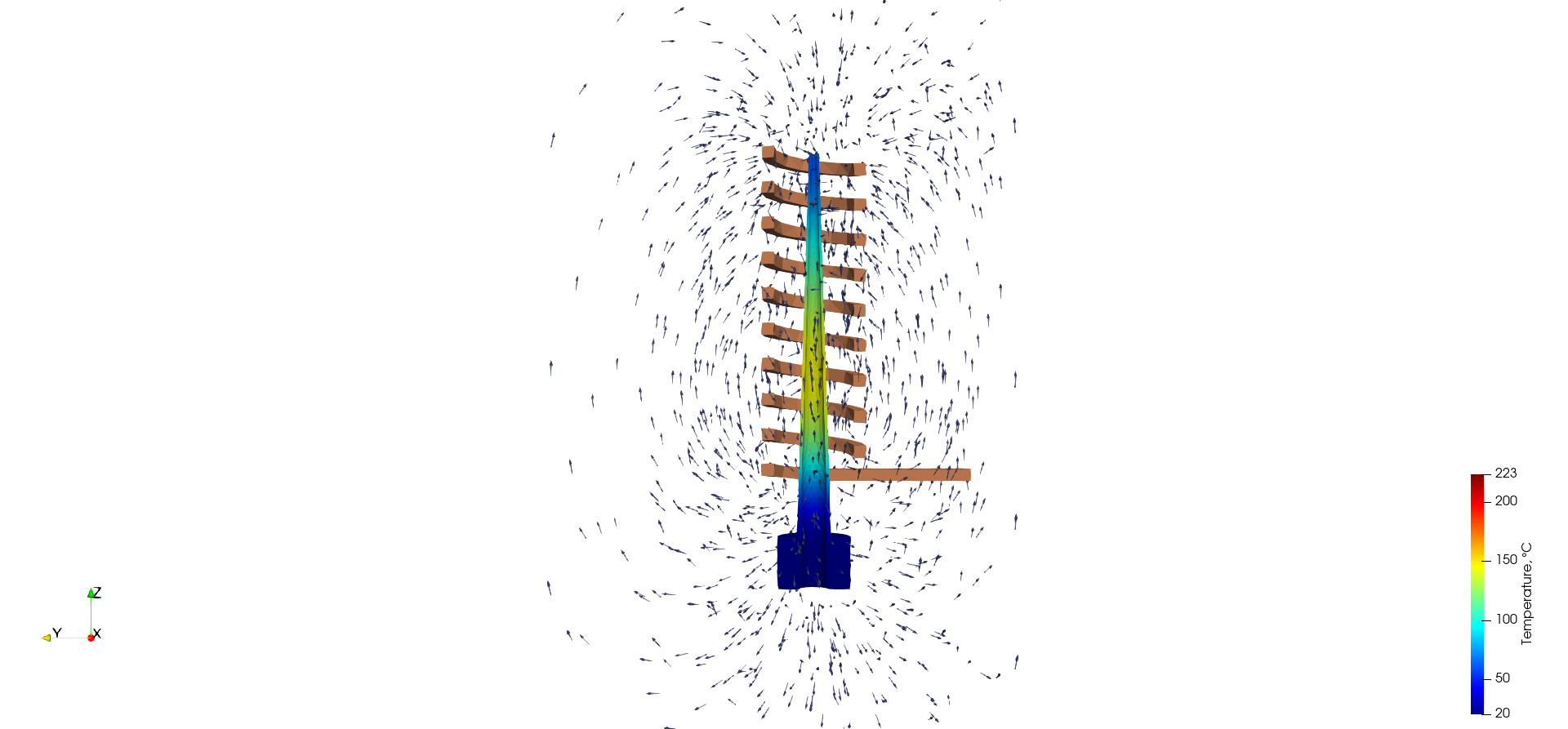

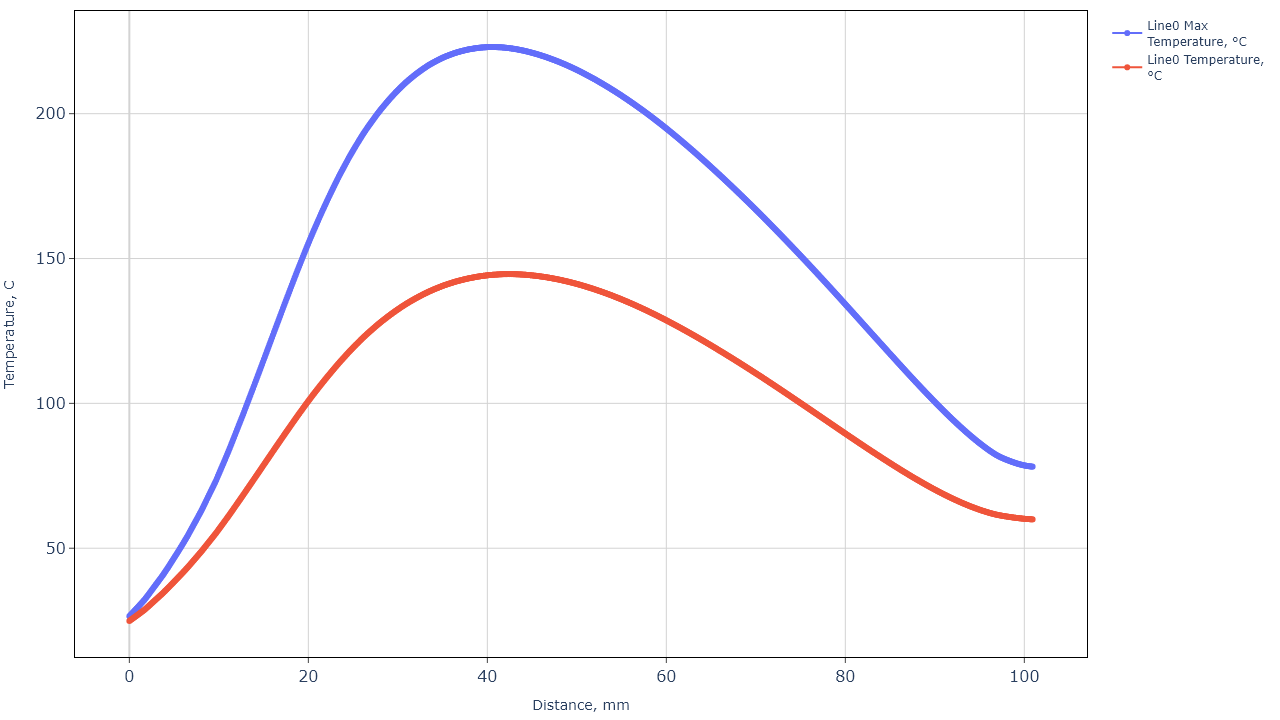

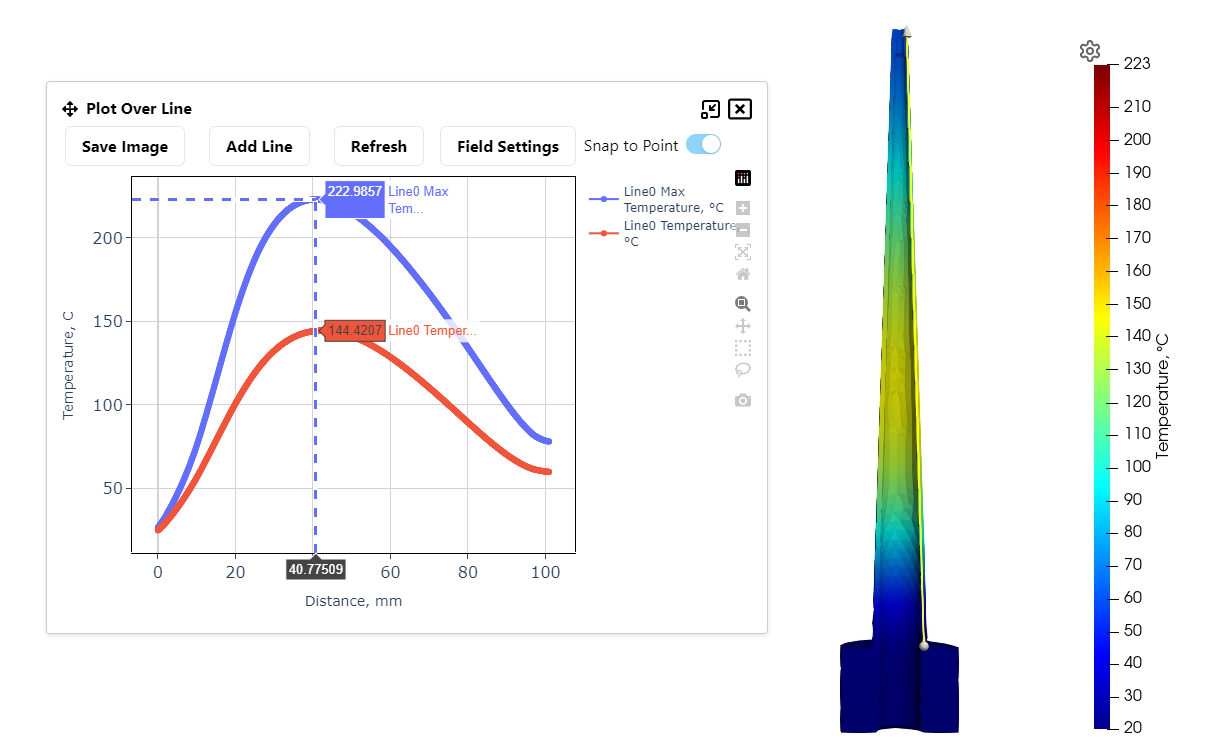

- Image 2: Here, the simulation shows how the temperature builds up along the catheter. You can see that it’s hotter in the middle and cooler at the tip, which is exactly what we want to maintain strength and flexibility.

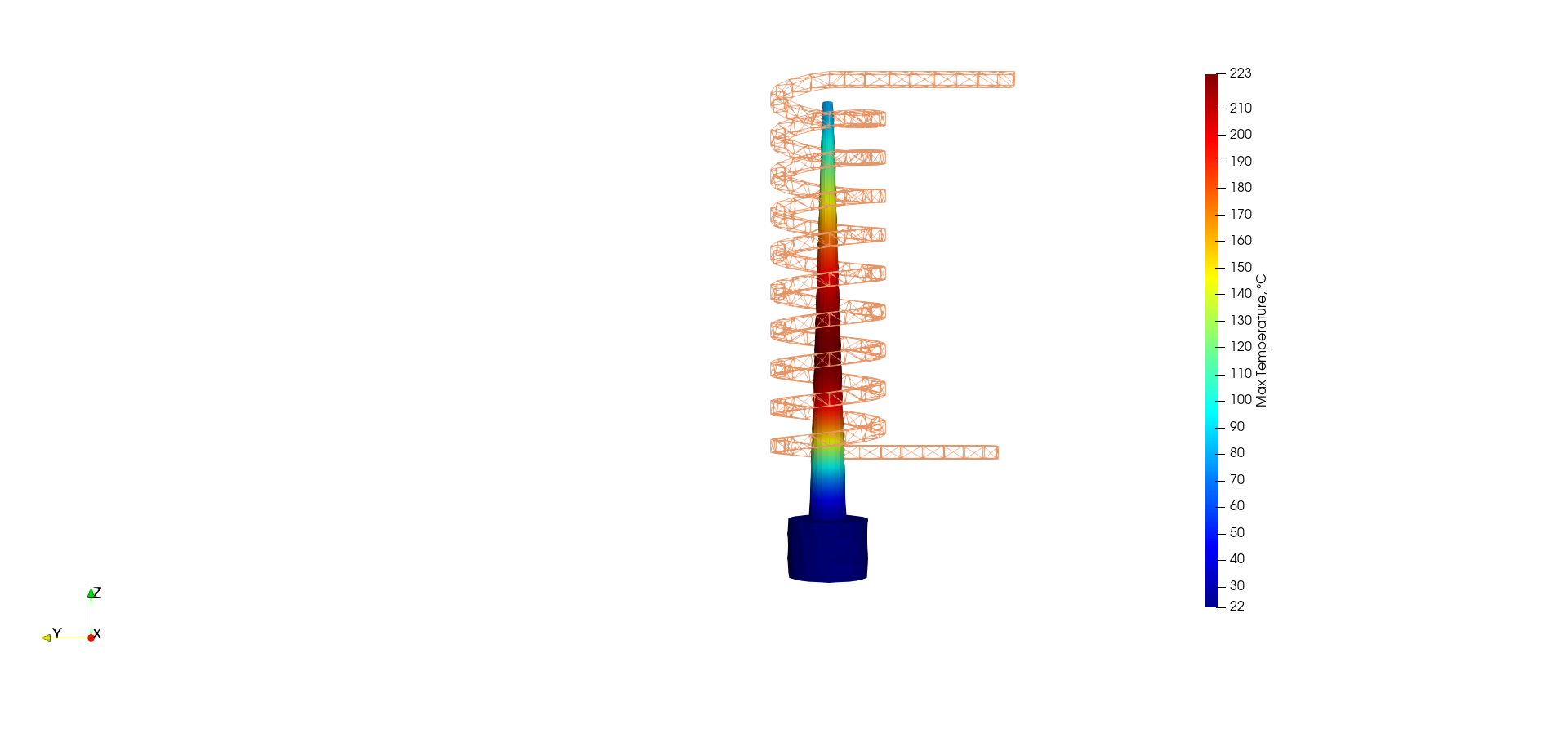

Image 3: This wireframe view makes it easy to see the temperature distribution inside the catheter, highlighting how evenly and precisely the heat is controlled across its length.

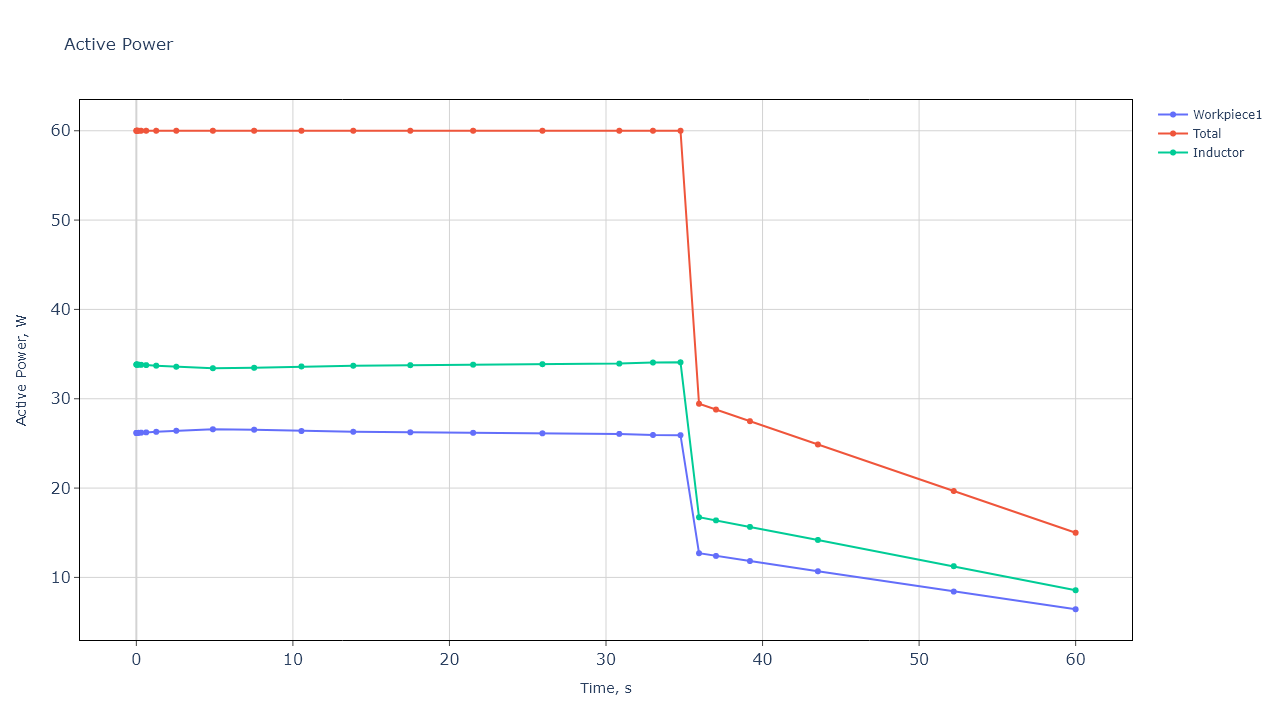

Active Power

Looking at the Active Power graph, the heating starts steady and controlled. Around 30 seconds in, we gradually decrease the power to slowly cool the catheter. This slow cooling is important because it prevents the material from becoming brittle again.

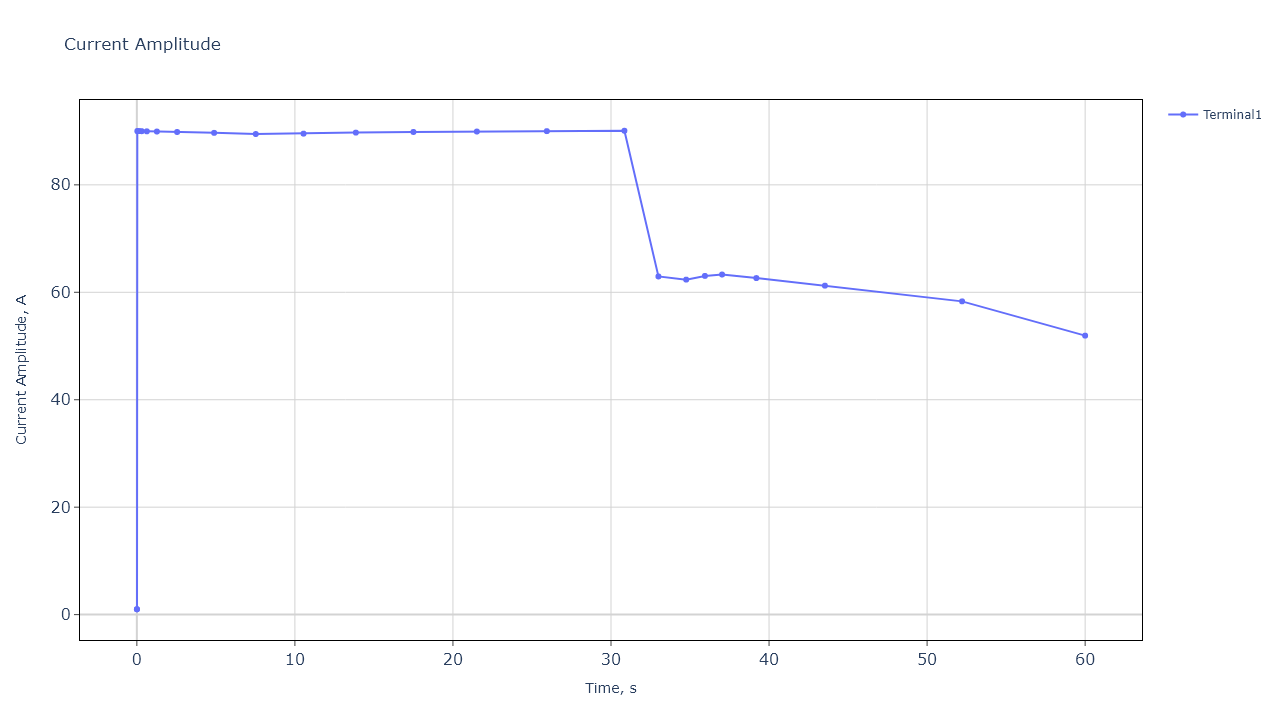

Current Amplitude

The Current Amplitude graph follows a similar story. It stays stable initially, making sure that there is consistent heating. Once we’ve reached the ideal temperature, we slowly lower the current to match the cooling, maintaining the right properties throughout.

It is important to note that once we reach maximum temperature, we do not cool the material very fast, instead turning the inductor’s power down slowly.

What’s the result?

By using the simulation, we achieved exactly what we set out to do: a catheter tip that’s strong enough to puncture skin, with a body flexible enough to handle pressure without breaking.

Temperature details:

- Temperature-Distance graph: This graph shows the targeted peak temperature (about 223°C) in the middle of the catheter. Meanwhile, the tip stays cooler at around 144°C. This perfect balance keeps the tip strong and sharp.

- Temperature visualization: Another detailed look shows how gently and evenly the catheter cools down after reaching its peak heat. This controlled cooling process makes sure that the catheter stays flexible and durable.

With this simulation we wanted to demonstrate how engineers can quickly test and refine their designs, cutting down on costly trial-and-error methods. Manufacturers can make safer, better-performing catheters more quickly, saving time and resources. Simulation software is not a rocket science, it’s a simple yet powerful tool. And most importantly, the software is not only used by big corporations but it is accessible to companies with any size.