Can computer simulation help increase induction coil lifetime?

The most common issues with inductors

Many induction coils are low maintenance, particularly the coils that are used on lower power densities and those without magnetic flux concentrators. If any leaks develop, the coils should be removed from production, cleaned, and repaired. In the worst-case – replaced. Let’s look at some of the most common issues with inductors.

Mishandling

Human error is usually to blame when inductors are physically damaged by improper care. They are often dropped, knocked off of workbenches, or not cleaned or stored properly – that can be avoided with good housekeeping and safety rules for employee training.

Arcing

Arcing may occur due to the coil coming in contact with the workpiece or it could be the result of foreign debris. Anytime arcing occurs, production should be stopped and the condition remedied. If the workpiece is hitting the coil, the condition could be from vibration due to restriction of the coil to the cooling water, poor position of the workpiece relative to the coil, or eccentric rotation of the workpiece.

Arcing across the turns of the coil or bus support of the coil is usually due to scale or oil contamination in the quench system. Better cleaning of the coil or scale removal from the quench system should be done. Another condition is arcing across the flux concentrator as it degrades.

Fatigue

Coils with high current concentrations can have flexure, particularly ar soldered joints that have abrupt changes in direction of the cooling water. This can ultimately cause the coil to fatigue and break. Also, some coils can have localized current concentrations, which can cause the coils to overheat and fail. Coils usually fail at a stress point, where there is an abrupt change in direction of the coil, such as a right angle with a brazed joint.

Deterioration of electrical contact

The bolts holding the coil or bus to electrical contact may loosen causing the current to flow through the bolt. This results in overheating and melting of both, with subsequent loss of current to the coil.

Degradation of the magnetic flux concentrator

All concentrators degrade with time in service. This is a natural phenomenon, the concentrator material degrades in time due to the intensity of the magnetic flux field and the heat from radiation.

Overheating

Overheating can result in coil failure. Water flow can be reduced by cooling system problems, or leaks can occur for any reason. Flux concentrators can also have insufficient cooling, resulting in overheating and premature failure. To fix this one must either increase the water flow by removing sharp turns, adding in-line pumps or larger cooling passages, or change the coil design.

The cost of time and materials to fix this leaking coil makes it a candidate for a complete replacement.

A better design will help

Inductor overheating can cause the coil to crack, crumble, “burn” or even melt. Overheating poses the biggest threat to induction coil lifetime, so an overheating coil needs either more cooling water or a better design.

Making a better design with multiple lab tests is the most common and traditional way, but is there a faster, cheaper way how to increase a coil lifetime? Enter simulation.

With the use of good design practices, one can improve coil longevity and improve production quality. By eliminating failure points in the initial design, proper material selection, improved cooling, and proper magnetic flux control, induction tooling life can be increased. Computer simulation has been proven to be an effective tool for predicting not only electromagnetic parameters of a designed system but also heat patterns in a given part and in the induction coil itself.

Case nr. 1

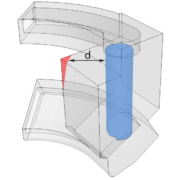

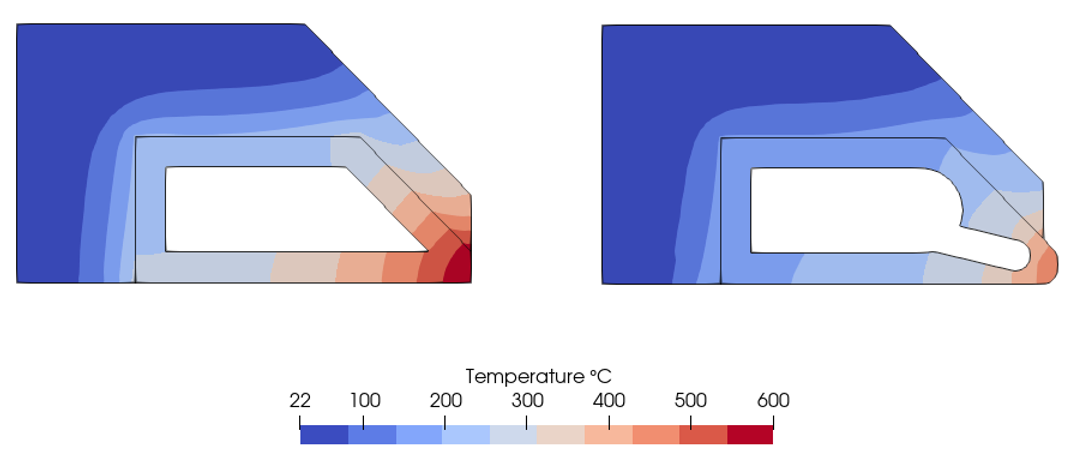

For the first case, a simple 2D wedge-shaped inductor profile with a flux concentrator was simulated at 10kHz.

The second case features a radically different cooling channel as well as a filleted nose and slightly cut concentrator.

To simulate the cooling effect from the fluid flow in the channel, a convection boundary condition was applied to the inside of the inductor. The heat transfer coefficient was decreased in the smaller parts of the profile to approximate boundary layer fluid effects.

The results clearly highlight the importance of cooling channel shape. In the first case, the nose of the inductor reaches over 600 °C.

You can find more information about a similar design in the article “Best Practice for Design and Manufacturing of Heat Treating Inductors” by Fluxtrol.

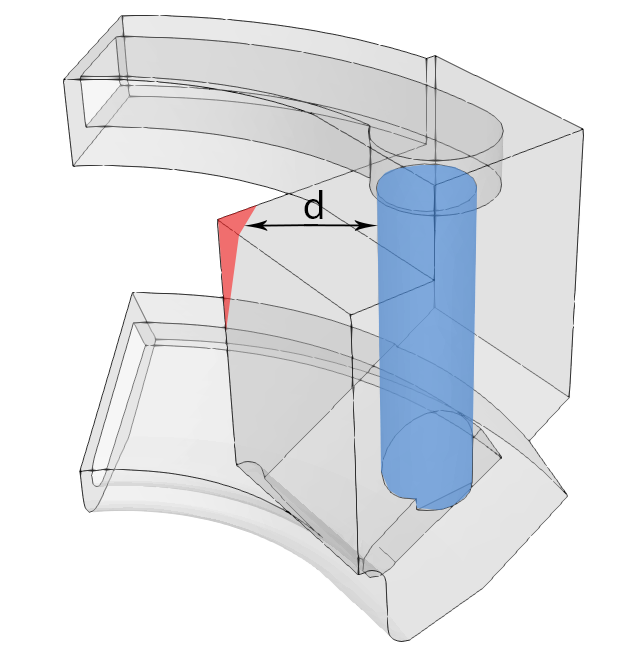

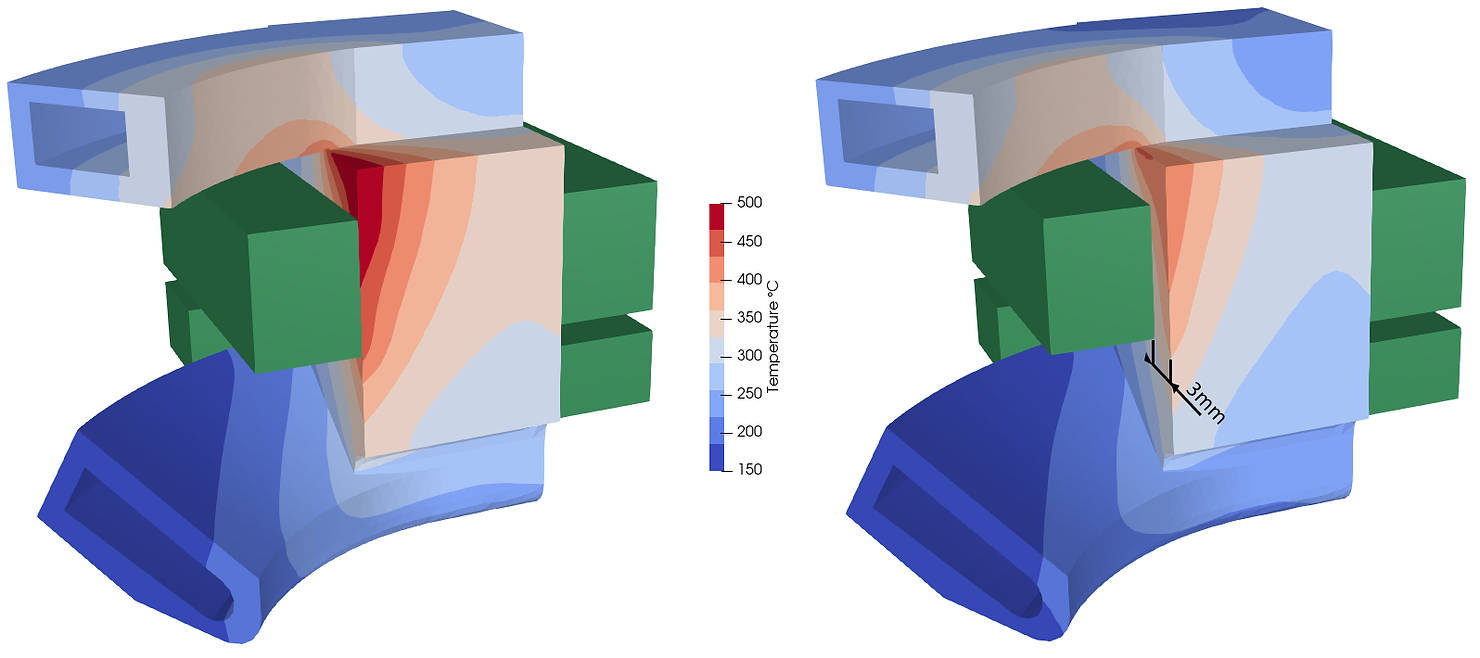

Case nr. 2

This is a case where a corner of the inductor was somewhat far away (d) from the cooling channel so it was overheating.

Most experienced induction coil designers will know how these changes demonstrated in this article affect the temperature distribution, however it is very hard to predict the magnitude of these effects. CENOS allows the user to explore these effects at various frequencies, powers, geometries saving countless hours of physical experimenting.

Reduce the number of physical tests and design time of induction coil and systems. Create heating recipes with confidence with CENOS. Start your free trial today or join our webinars to learn more.